In my first blog on the Trade Partner Daily Huddle series, I covered a bit about my introduction to Lean Construction, planning boards, huddle tools, and topics for small projects. In today’s blog I’ll share some key components and aspects of our Large Project huddle.

Large Project Huddle

On our larger projects where we have more than 5 team members (“a large crew”), the foreman is not always working directly beside each of the team members. When they have a question or are looking for information or clarification, they will stop their work and go look for the foreman before continuing their work. On a large project with a complicated site this can easily burn 30 minutes or more just looking for the foreman; this waste accumulates quickly when it is spread across a crew of 20 people.

The foreman generally has a huge amount of information, schedules, people, and details to remember. That they need to collect, distill, and disseminate with the site and their teams. The daily huddle provides a venue to organize and share information with the entire team in a structured manner. Bringing information that is relevant to the current state of the work and the site improves team communication and ensures everyone understands today’s commitments and expectations. The daily huddle uses a shared leadership and team learning approach to develop the entire team.

As our projects become larger the huddle process and production boards take a bit more work to setup and maintain. But once the foreman has the huddle set up and running, it becomes routine and easy to maintain very quickly. After implementation most foremen found that the number of calls from their employees dropped from 10 calls per day down to 1 or 2 calls.

- The Benefits: The huddle and production planning set our teams up to proactively plan and commit to the weekly workplans at the site. It positions the foreman to collaboratively contribute at the daily trade partner meeting. While focusing our entire field team on the completion of our customer’s projects. The huddle provides a daily check on construction progress, quality, and Kerr’s continuous improvement.

- The Format: The huddle is still held to 15 minutes in duration and comprised of a Daily Meeting with a production board and markable site map. The meeting is a Lean-held format that starts on time and ends on time. Every project team is expected to have a daily huddle, and everyone on the team is expected to attend.

Large Project Huddle – Components & Agenda

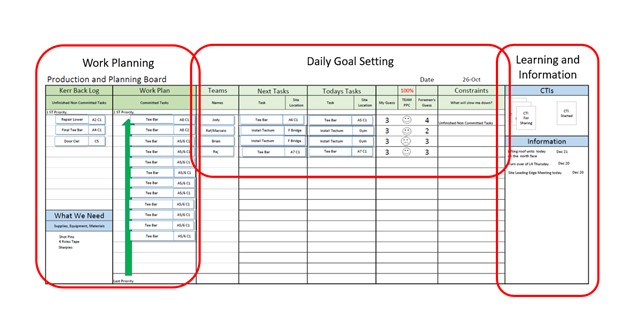

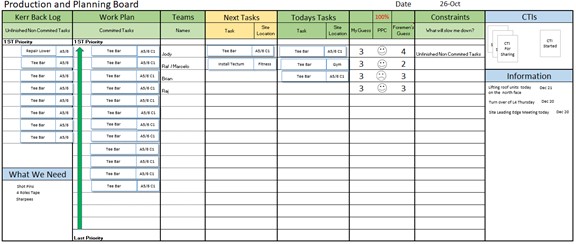

The production/planning board is divided into three key segments:

- Weekly Work Planning,

- Daily Goal Setting, and

- Learning and Information.

In our next blog we share the details and flow of the Production Board and how it is set up and used to engage the trade teams in the site build.

In our next blog we share the details and flow of the Production Board and how it is set up and used to engage the trade teams in the site build.

Weekly Work Planning

The work planning area of the board is the list of this week’s scheduled tasks and all the non-scheduled work the foreman is planning to complete on the project. Most foremen already keep this list on their schedules, in their heads, and in their notebooks. They are continually adding, subtracting, reorganizing, and adjusting these lists as they travel around the site coaching and communicating their plans to their team members. When we take those lists out of the heads of the foreman and post them on a board so their entire team can see the upcoming work and site commitments, we see a shift in the ownership of the build from the just the foreman to the entire trades team.

As a foreman, if you want your trades team to be collaborating and actively building with you, you need to show them your lists of work. When your team can visually see the tasks of all the work you have up on your board, they will also see the work move from the work plan to the next task, to today’s task, and then to the completed pile. This cycle allows them to see the workflow while providing them with a sense of completion that is achieved with their actual assembly of the building. The sole action of taking these lists out of the foreman’s head and putting it up onto the board is the key to transition the ownership from the foreman to the entire team of workers.

Daily Goal Setting

The goal setting part of the production board is where we begin to shift the trade team from thinking and being reactive to becoming proactive. Each trade person or work team has their own lane on the production board; this lane that is used to load their work tasks into either “Today’s Task” or “Next Task.” (NOTE: at the end of this blog, I share details on how to define and break down tasks into manageable durations.)

- Today’s Tasks: When Today’s Tasks are assigned the trade, they are asked in the morning meeting to consider how long they think the task will take to complete. Their guess is written on the board by the trade person; the foreman will also add how long they think the task will take into the Foreman’s Guess column. If there is a significant difference between the two guesses, a collaborative discussion is had to ensure we understand the approach and constraints associated with the task. The discussion continues until they align on similar durations. When the team members conduct goal setting in this collaborative manner, we reduce the number approaches to the work and the overall variation in task durations across the site and company. This improves pull plan tasks and duration setting with closer actual work times.

- Next Tasks: We also assign the Next Task for each trade or team. When the trade people know what their Next Task is they typically take the time to look at the upcoming work area as they travel the site to ensure it is ready for them to start work. They note what they need for tools and materials and if the area is clear and ready for their work to start. If it they are missing things, or if the area is not ready, they raise it as their lane is reviewed with the foreman during the huddle. This allows the foreman to get in front of the work to resolve or escalate the constraint at the site’s daily trade partner meeting. By having the next task on the board, we reduce setup time and improve overall readiness across the site.

- At Tomorrow’s Goal Setting: The team starts the goal setting by asking about today’s work tasks (Now Yesterday’s Task). Were we able to complete it or not? How long did it take and was our guess right? If they were successful, we add a Happy Face in the Team PPC column and celebrate the success with a high five or success vocalization. Our team members need a win, so when we check a box or complete a task, we celebrate with a shout out. These high fives and celebrations satisfy our physiological condition, through something calling the Sargonic effect, where we get a little shot of dopamine when we celebrate.

If we were unsuccessful, we place a Sad Face in the Team PPC column and have a quick collaborative conversation on what happened. How can we improve for the next time? Or how can we approach the task differently? This step is conducted with the whole team; the team learning approach improves the quality and speed of the future work across the team.

As we go through each of the tasks in the lanes, we remove the completed tasks from the board and move the next tasks into the today’s task column. Then we start goal setting for our new Today’s Task.

- Daily Work Assignments and Planning: Work can be assigned on the fly in the huddle or by the foreman after the huddle. Work tasks are selected, starting with the task at the top of the list in the work plan column. The foreman looks at the task, considers the resources needed and capabilities of their team, and places the task into the Next Task column for those assigned trade people. Once they have assigned the committed work, they look at the Backlog column to see if any of those tasks can be sprinkled across the team and the board.

- Team PPC Score: At the end of the meeting, we add up the number of happy faces, calculate the PPC for the team, and write it on the top of the board for the team to see. Typically, on our trade partner board we will be hitting above 90% on our commitments. This is necessary if we want to average 80% PPC at the site trade partner meetings.

Learning and Information

Sharing information with your team is important. Everyone on your team needs to be on the same page. We keep both company and site information that needs to be shared with the team in the same location. After the foreman reviews his/her emails or meets with the project managers, they update the board with the new information. The site-specific information is added to the board after the daily trade partner huddle.

- Information: The information stays on the board for 2 days. If one of the team is sick, they are generally gone for a day here and there, so when we keep the information on the board for 2 days, we are able to review the information from yesterday with those individuals. We have a Kanban, where the date is written behind the information and erased when it is older than 2 days. It is critically important to not let the information get stale on the board if we want people to pay attention to the information that is on it.

- Continuous Task Improvements (CTIs): A key component of Lean is to take the time for improvement. When we have a collaborative task discussion around quality or speed and looking for better approach, we document it and place it on the board until we have completed a trial. We do this in a team-learning environment to give everyone a chance to consider and chime in on the solutions we are developing. After we try the new method and review our improvement, we share the results of our trial with the rest of the company.

Click here to download an agenda for before, during, and after a large project daily huddle.

Daily Huddle Tools

The large project daily huddle uses the following three key tools to share the plan, organize the work, and engage the team:

- Planning Board,

- Markable Site Map, and

- Daily Huddle Agenda.

Planning Board

The planning board is used when the foreman has a trades team of 5 or more people.

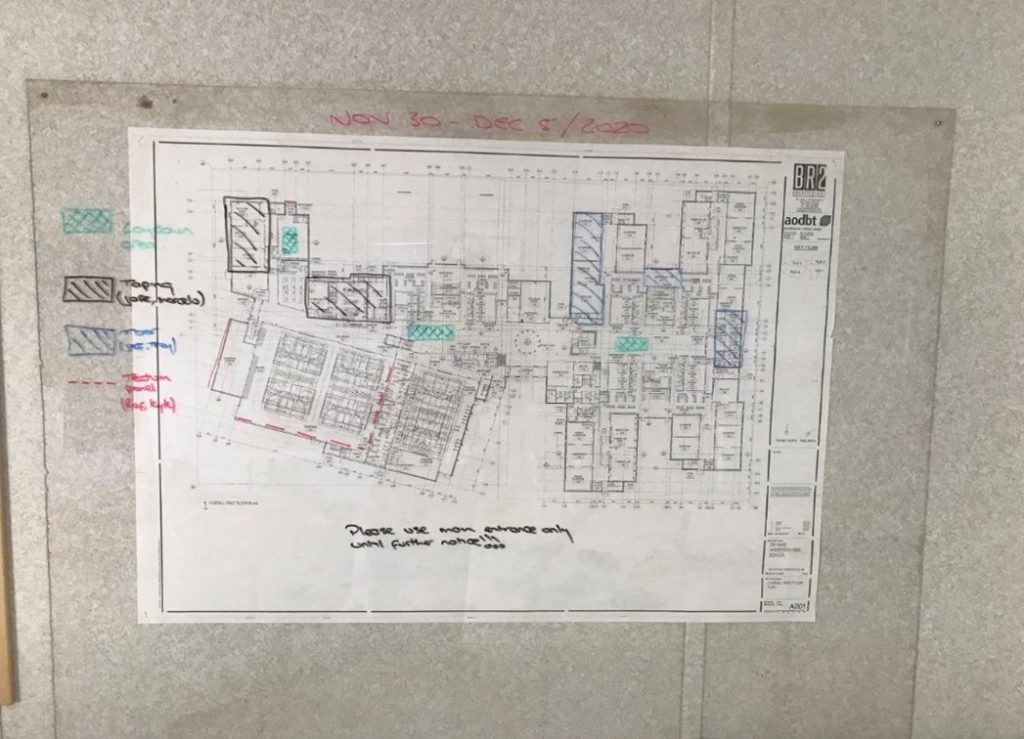

Markable Site Map

Markable Site Map

The markable site map is used to visually communicate and clarify production information with the individuals and the team. The visual allows the foreman and team members to:

- Point to an area to clarify location and expectations of production tasks,

- plan materials and supplies lay down locations, and

- Set the travel path to and from work areas.

Daily Huddle Agenda

Daily Huddle Agenda

Discussed in detail earlier in this blog post, the daily huddle agenda helps the foreman and trade partners communicate and collaborate.

Click here to download an agenda and outline to use for before, during, and after the large project huddle.

Engagement Enhancers

A key part of the Daily Huddle is to transfer the engagement toward a successful build from only the foreman to the entire trades team. When the team is as invested in the success of the project as the foreman, the likelihood of a high-quality, on-time completion is greatly increased.

Knowing this we incorporate each of the following engagement enhancers into our huddles:

- Assign Roles & Collaboration: Regardless of project size, we incorporate shared leadership to increase the team’s engagement in the overall build. When we invite team members to take ownership, participate, or share their thoughts and opinions, we raise the bar on our planning and success. Our huddles are designed with this in mind, and we advocate for the foreman to actively assign leadership roles and engage the trade partners to collaborate.

- Rotate Huddle Facilitators: There is no reason that the foreman must run the daily huddle. In fact, we found when we reduced the percentage of time the foreman is talking during a meeting, the team’s engagement increased. At our large project huddle, we invite team members to rotate presenting and leading the daily huddle.

Using a Spin The Wheel app we found, we enter everyone’s name as a potential leader. Each morning, just before the meeting, we spin the wheel. The person selected leads the team through the huddle. This shared ownership for the huddle process to grows the team’s collaboration and leadership and allows the foreman to focus on the critical discussions around constraints and goal setting.

And once the team is trained, this approach works even in a pinch without a foreman. One day we had a foreman who was delayed in traffic. He called into site with the intention to lead the meeting over the phone. The team shared proudly that they had completed the huddle without him in attendance. When he arrived onsite, the team members were all productively working on the tasks on the production board.

- Share Huddle Leadership: The Safety Toolbox, The Leading of Stretches, or The Sharing of Key Information are all opportunities for a foreman to assign volunteers to deliver a part of the huddle. Whenever possible, we look for opportunities to assign interested parties to take the lead of these segments or our huddle.

- Transparency: When we provide our team with an environment, information, and equipment to be successful, they make decisions differently. The huddle shares information about our project and progress towards the goals, including the key milestones and the timeline and financial status to our end goal.

- Celebrate the Wins: It’s easy to forget to stop and celebrate our wins and completions along the way (especially in projects that span a year or more). Our teams need to see that we are interested in their success and our overall continuous improvement during a project and at a project’s end.

Our huddles are built to include daily goal setting for both the teams and individuals. We document these individual commitments and review how we performed against those commitments daily, and we slow down and celebrate the wins each day. This gamification and celebration step allows our people to feel good about their contributions and results as a more engaged team. Each person receives a shot of dopamine when he/she/we achieve a goal or check a completion box.

Task Tips

Understanding what qualifies as a “task,” be it a Today’s Task or a Next Task is a central training aspect we share for huddles.

- Task Duration: The effectiveness and productivity of the team can be impacted by task size. If we have a trades person who we assign 4 days of work, when we check in on Day 1, they typically have no issues and often a low sense of urgency on getting the task completed. On Day 2 when we check in, they start to think that they could have gotten more work done on Day 1 but are reluctant to let you know. When you check on Day 3, they realize that it is highly unlikely they will finish on Day 4. So sometime after lunch on Day 3, they ask you for an extra day to complete the task. At this point it is too late and you are now 25% over schedule with no plan to catchup.

Project Managers typically work in weeks. If we are executing our construction in weeks (assigning tasks of that duration), we will find that these tasks are continually interrupted by other site priorities. These interruptions break the focus of our trade people doing the work. This can be frustrating to those team members and desensitizes the impact the team feels if we fail to achieve our commitments and schedule dates.

There are many, many moving parts in construction today, so as a result, things change and move around the site and the schedule. We need to be flexible and set our team up for success by planning in a task size that is achievable. Instead of the 4-day tasks, I like to break them down into 1-day tasks at the most. This will ensure that as we check in each day, I know if we are ahead or behind on our commitments. This is the maximum duration we want to plan our work schedule, as it allows us to see progress towards our weekly commitments. The 1-day duration is easiest with a highly skilled, experienced, and trained team. These tasks are less likely to be interrupted by the site chaos and changing daily priorities.

- Tasks That Are Hours in Duration: If we want to create the best opportunity to achieve our “Commitments,” we need to ensure that we break our tasks into the smallest possible unit – otherwise known as the task duration. Regardless of the skill of the team member, when we break our tasks into 2- to 4-hour segments, we can easily go back and assess our progress to completion and respond by moving resources or extending hours to complete the task. Smaller tasks also allow for richer discussion about what worked and what did not work when we debrief in our daily huddle. A lot of things can happen over eight hours, so it’s harder to assess what we could have done differently when we review later.

We’ve found that before coffee, before lunch, and after lunch are the best task durations to assign. When we operate with these durations, we find additional work hours that can get lost with full-day tasks. The approach matches the cadence of the team, and they respond well when you task and pace relative to their breaks. With most trades people it’s normal conversation at coffee and lunch to check in and see how team members are doing. This touchpoint allows for an unofficial check in on progress (good or bad), allowing the foreman to respond by adding additional work tasks or by asking them to assist others so that the whole team can be successful at the end of the day.

- Task Interruptions: In the field, interruptions to the tasks that our people have started to work on is very costly! The waste looks like this: they must stop, contact the foreman, wait for the foreman, troubleshoot the issue, and then wait for information before they can resume work.

In today’s construction environment where site priorities often shift daily, I can say with a high level of confidence that:

-

- 100% of the tasks that are planned for more than 1 week will be interrupted.

- 80% of the tasks that are planned for more than 4 to 5 days will be interrupted.

- 60% of the tasks that are planned for more than 3 to 4 days will be interrupted.

- 10% of the tasks that are planned for 1 day will get interrupted.

Reducing interrupts ultimately reduces waste, and reducing task size, reduces interrupts.

Give Huddles a Try

At a larger construction site, where we are working with multiple trade partners and there is some level of complexity to the construction build, it is difficult achieve the workflow without tools to get us there.

The large project huddle, shared throughout this blog, is designed to simplify the planning and assignment of the work tasks across the site. When we link this planning process to the commitments you are making at the site level trade partner meeting, we improve the overall site performance. In sharing our approach in this blog series, I’m hopeful that trade partners will give all or part of our huddle a try at their own project sites.

In our third and final blog in this series, we will focus on our Large Project Production Board. We’ll cover how it is set up and used as a visual system in the daily huddle.