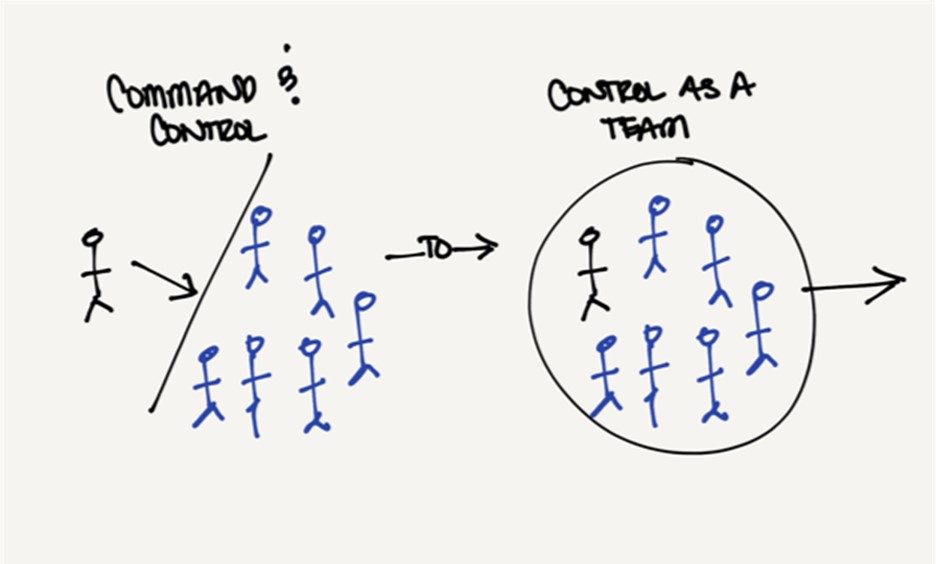

I would imagine many of you are in some way familiar with the Last Planner® System (LPS); maybe you know quite a bit about it, or perhaps you’ve only seen references to it at some point. Wherever you are in that spectrum, awareness of LPS is good because it is bringing collaboration, trust, trade partner engagement, and respect for foremen back to our industry. It’s allowing us to go from the old “command and control” world to an integrated form of control with the team.

Command & Control vs. Integrated Control

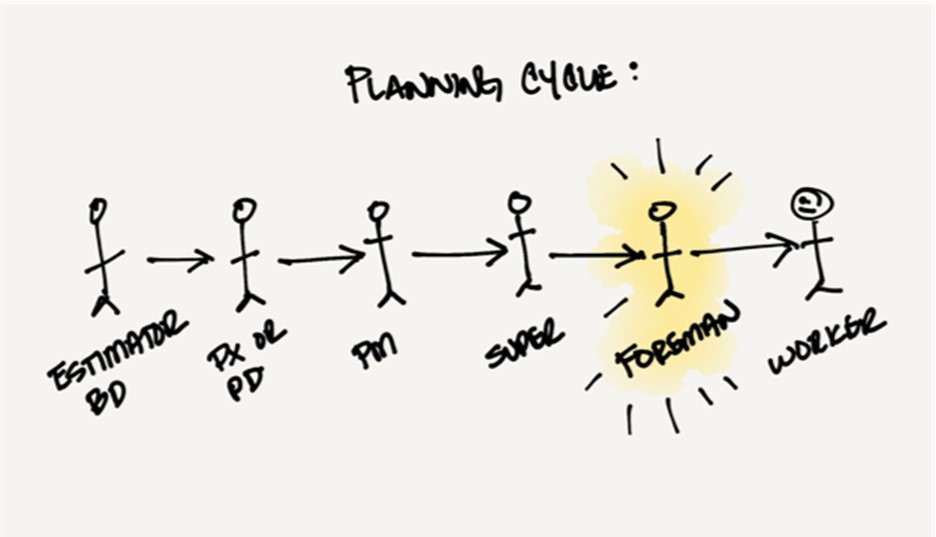

At a high level, to me, LPS is a system of meetings, behaviors, and practices that enable the last planners (trade foremen, superintendents, etc.) to participate with, have influence in, and commit to the planning of a project or phase at a short-interval level of detail for sequences in pull plans, look-ahead schedules, and weekly work plans. They are called “last planners” because they are respected as the last key planner in the project planning cycle.

Where does the Last Planner Fit in the Planning Cycle?

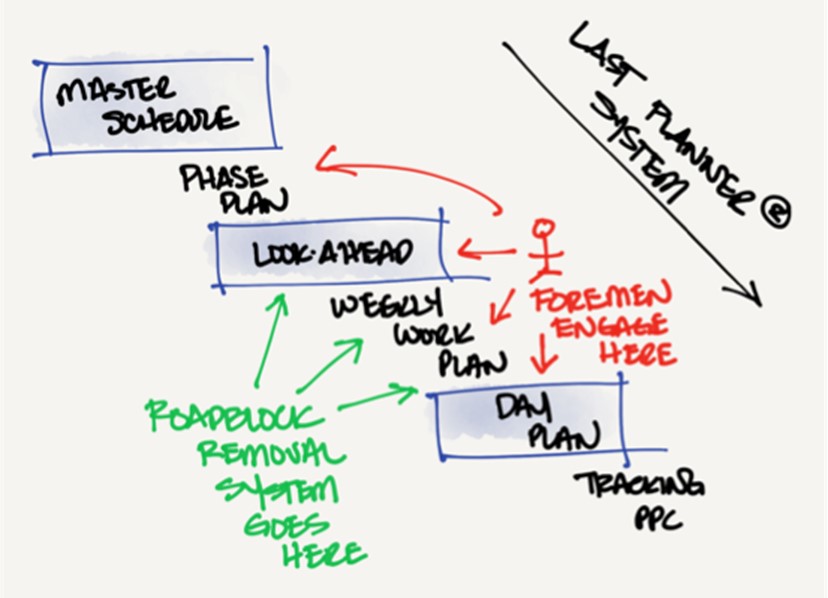

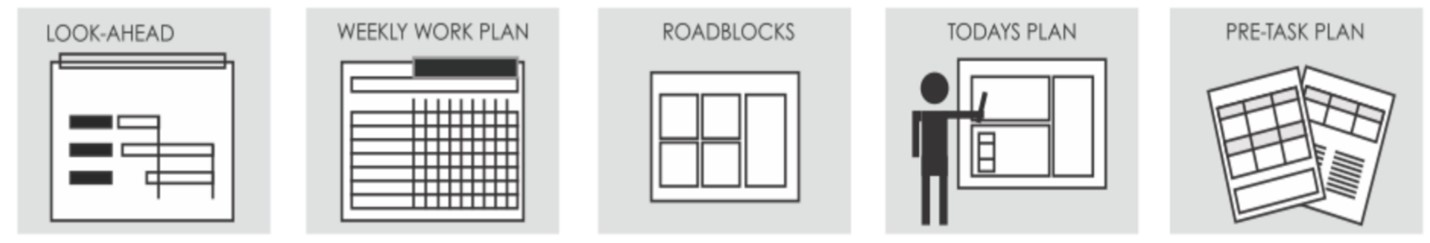

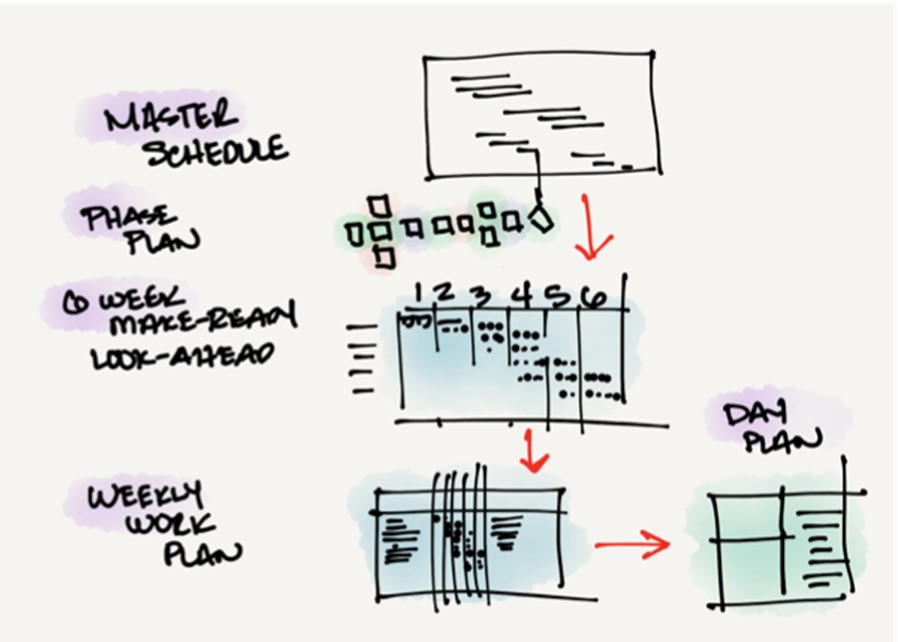

The scale of that planning detail is shown through five key schedule formats:

- Master Schedule

- Phase Plan (created with pull planning)

- Make-ready Look-ahead Schedule

- Weekly Work Plan, and

- Day Plan

These formats provide the schedule information in a visual way so our last planners can collaborate, commit, execute, and reflect together as a team.

The Last Planner® System:

So, what do these scheduling formats do for us? Well, let’s show that below in bullet form:

- Master Schedule is the project schedule that plans the entire project at a high level, identifies overall project durations, and clearly shows project milestones. This is used for, “master” planning. So, the Master Schedule gives us…milestones!

- Phase Planning is typically done with a process called pull planning. This process allows the foremen to and project team to collaborate on the proper sequence of activities in a phase. This phase plan is then entered back into the master schedule or transferred to the project planning boards. So, the Phase Plan gives us…a coordinated sequence!

- Make-Ready Look-Ahead has two purposes. First, it helps the team align resources to the more accurate dates and, second, it helps the team see and remove roadblocks. This plan should be visible for the project team and foremen. So, the Look-Ahead gives us…on-time resources!

- Weekly Work Plan’s purpose is to make commitments and lock in dates for the next week. Foremen collaborate, make commitments to each other, and coordinate a solid plan for the next week. So, the Weekly Work Plan gives us…a coordinated plan for the week!

- Day Plan is the executable plan for the next day with input from all the foremen. So, the Day Plan gives us…the detailed steps to execute tomorrow!

The Progression of Deliverables:

Here is a plot twist for us. The Critical Path Method (CPM) is not the only form of Master Schedule. Takt planning is also a viable and preferrable solution. Here is the difference:

CPM is a system that relies on logic and an algorithm to create what is called a critical path. Once a main structure for the schedule (or “work breakdown structure”), is created in the scheduling system, sequences are built within the schedule and then all activities are logic tied together. The CPM system then runs an algorithm (known as a forward and backward pass) to create float calculations and targeted start and end dates. Once the schedule is complete, you will have a schedule with a critical path and milestones that fit within the system. These milestones are then used for LPS as targets from which you can pull plan. All other detailed scheduling is then done in the Last Planner® System. Your Make-Ready, Weekly Work Plan, and Day Plans are managed visually, as an active and visual information system your last planners can use in your huddle areas.

Last Planner® System (LPS) with Critical Path Method (CPM):

Takt planning is a scheduling method that is:

- highly visual,

- shows all three types of flow,

- is scheduled with rhythm, continuity, and consistency, and

- that (most importantly) has buffers.

Because of this, it allows the project to be scheduled with one-process flow, which limits work-in-process, and has a reasonable project duration. These are key considerations if you want to finish on time, with good quality, and without a crash landing at the end.

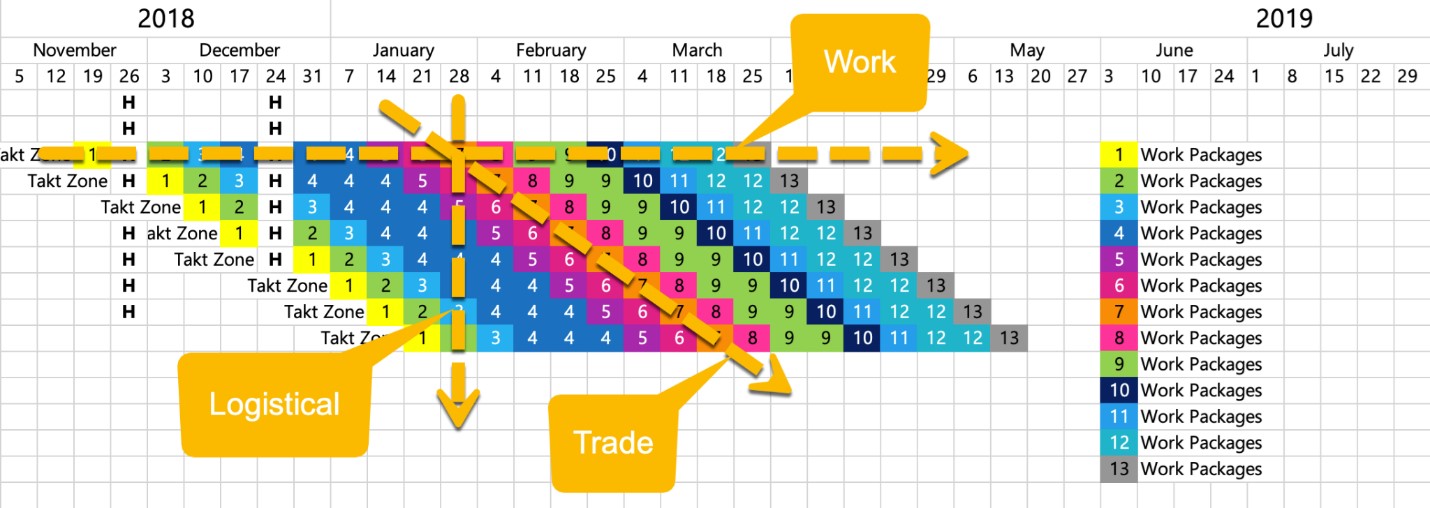

A Takt Plan:

I prefer Takt plans because they follow production laws, increase labor productivity, create stability on the project site, and allow you to see your problems sooner so they can be fixed. We will have more about that in later blog posts. But suffice it to say, Takt planning rocks, and you will love it!

As shown below, you start by breaking your project up into zones. Next comes pull planning representative zones by area type, and finally they are packaged into a Takt plan. All other schedules in LPS are then derived from a schedule that has flow, which is important for leveling worker counts, materials, and cost reduction.

Last Planner® with Takt:

Before I close, here are a few questions for you to think about…

- Do you find that most schedules still have unrealistic durations?

- Do you find that most projects are planned without buffers?

- Do most of your schedules stack trades and plan unrealistic work?

- Do your master schedules typically print on 50+ pages without any real way to quickly understand the plan?

- Are your schedules built without flow?

- Is it hard to see when you have master schedule problems?

- Do you hate already being behind when you start the project?

If you answered YES to any of these, I invite you to continue with this blog series and stay with us as we bring flow back to construction!