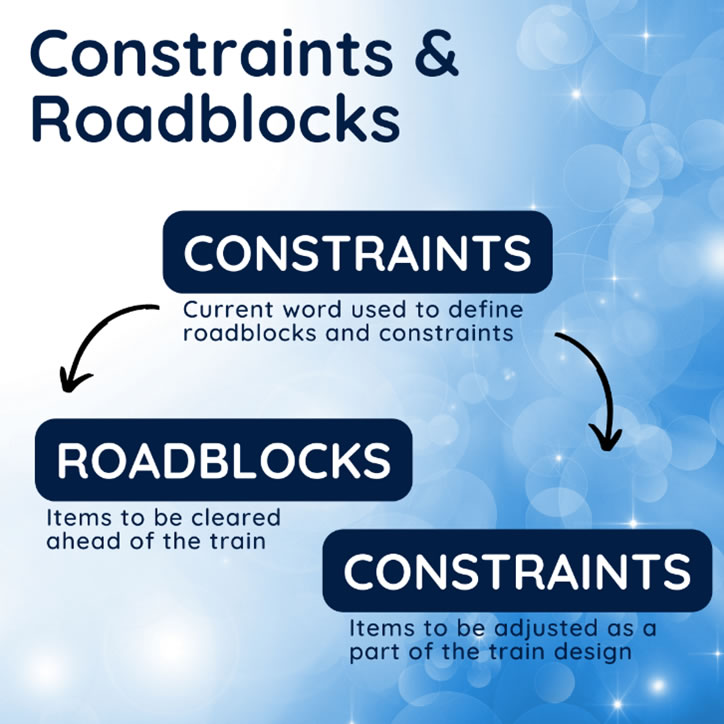

Calling possible and actual variants “constraints” was a great start for better construction management. Now, it’s time to split the term and call the roadblocks “roadblocks” and to call the actual constraints “constraints!” By introducing the proper use of these terms for our Last Planner meetings, we will all reap success.

I’m not picking a fight and don’t criticize anyone who has used the term constraints to encompass both “constraints” and “roadblocks.” The term has served us well.

But the time has come to define and separate out the term “roadblocks” for the Last Planner System. We will have better results, and it will frame our vocabulary to prepare for the current and inevitable pairing of Last Planner with Takt & Scrum.

Let me explain…

What is a constraint?

One definition for a constraint is a “limitation or restriction.” Words like restriction, limitation, check, restraint, control, damper, rein, and hindrance are associated with the word. The Goal by Eliyahu Goldratt of Theory of Constraints’ fame defines constraint as: “the limiting factor (i.e., constraint) that stands in the way of achieving a goal and then systematically improving that constraint until it is no longer the limiting factor. In manufacturing, the constraint is often referred to as a bottleneck.”

Constraints in project conditions and zones are permanent or semi-permanent. They are things that, once improved as best we can, we just must deal with and plan around. They are dealt with differently than a roadblock. They are accepted, adjusted, and improved as a part of the production system. In fact, the system is designed around it or with it in mind. Constraints for trades and crews are production rates, crew composition, crew labor availability, or zone configuration. These are planned, leveled, optimized, and improved as a part of the Takt Steering & Control System and cannot be entirely removed—just improved.

What is a roadblock?

One definition for a roadblock is “a barrier of barricade on a road” or “any hindrance.” Words associated here are barrier, barricade, blockade, obstruction, or checkpoint. A roadblock is anything that can hold up the progress of work done in a sequence or train of trades in construction. Whether you imagine that sequence of trades as a train (like in Takt Construction) or a caravan of cars on a road, the point is the same—the roadblock will hold up the flow of work or the train of trades, and it is ALWAYS removed to create flow. ALWAYS.

Why does it matter?

Reason 1: Words matter, and we want to signal the right action for the right word.

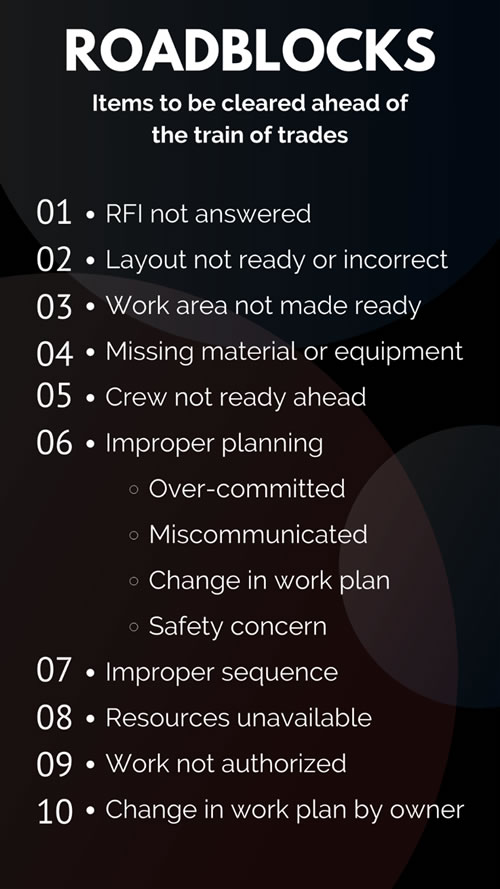

Most references to constraints in construction are actually roadblocks. Meaning, the items shown on constraint boards are things that, if not removed, will slow or stop the train of trades from moving effectively through zones. They must be removed. They are not accepted as permanent. So, they are not constraints. They are really roadblocks. The signal that we should receive when we hear about a roadblock is to “REMOVE IT IMMEDIATELY!”

In the text and images below, I’ve categorized the typical variances in the Last Planner System into both definitions.

Let’s look at how they shake out:

Constraints most often appear during the planning process in pre-construction as part of system design. The following examples are typical constraints we may find:

- Configuration of site,

- Assembly of the contracts and crews, or

- Unforeseen existing conditions.

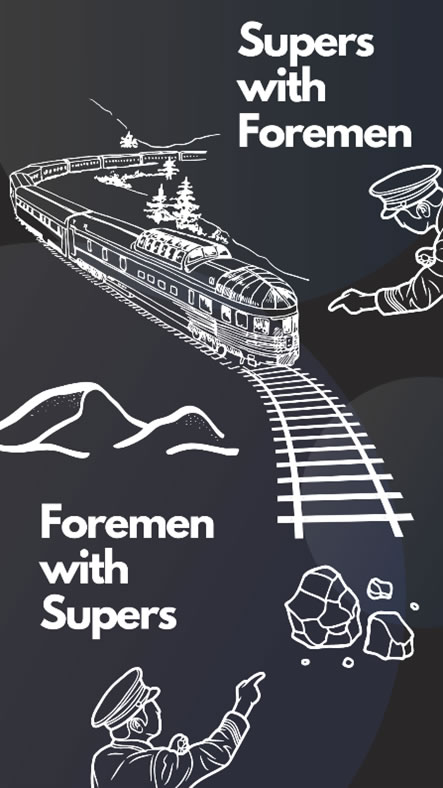

As you can see from the list, most things that we want foremen to be finding and removing with supers are roadblocks, not constraints. And conversely, most (if not all) constraints are managed as a part of the system design in the Takt planning and Takt steering efforts by supers with the help of foremen.

If you have a constraint (a permanent or semi-permanent condition), the signal we should receive is to “REMOVE IT IF YOU CAN OR OPTIMIZE & IMPROVE IT” and, after that, “PLAN & WORK AROUND IT.”

Planning and working around a constraint could be manifested in a few ways if we:

- Remove the step, process, or item;

- Add additional capacity; or

- Improve the step, process, or item.

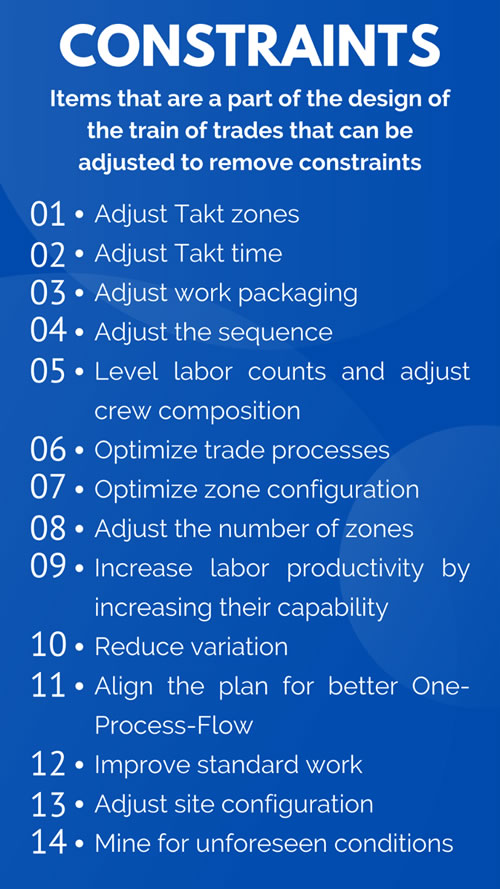

And more specifically, we optimize constraints on a project only with Takt planning, steering, and control when we do the following:

Addressing constraints is the first step.

Here is another point: all constraints should be removed, optimized, or improved before the work begins. Meaning, we should have the best plan that works around all permanent or semi-permanent constraints, all crews going at the best speeds, all areas configured in the most ideal ways, and all other conditions that exist in the most ideal state before work begins.

Now, the only things that should show up in the way are temporary things that could get in the way of the crew—meaning roadblocks. The Takt steering and control system will handle the constraints based on tracking the production plan.

The point here is this: foremen and supers LOOK AHEAD and remove roadblocks as a leading indicator system. Constraints or bottlenecks are tracked as a lagging indicator system, and adjustments are made from there by supers with foremen based on data and analysis.

You know it’s working when it just flows.

Here is another way to look at it. When a project is in flow, you find a group of crews (trade processes) in a phase of work that are:

- Working toward the SAME long-term plan,

- Going the SAME direction,

- Moving in the SAME sequence,

- Providing the SAME amount of value (energy or effort) to each zone,

- Receiving the SAME amount of work or value in each zone,

- Going the SAME speed,

- Being the SAME distance apart,

- Receiving all needed resources to perform the work on time,

- Being on the SAME team,

- Working toward the SAME short interval plan,

- Given the SAME level of respect and input, and

- Flowing without stops and restarts.

If we look at how these same efforts are governed by a scheduling system, you will see:

- First Planner System (Takt Production System)

- Working toward the SAME long-term plan

- Going the SAME direction

- Moving in the SAME sequence

- Providing the SAME amount of value (energy or effort) to each zone

- Receiving the SAME amount of work or value in each zone

- Going the SAME speed

- Being the SAME distance apart

- Scrum

- Receiving all needed resources to perform the work on time

- Scrum AND Last Planner System (LPS)

- Being on the SAME team

- Last Planner System

- Working toward the SAME short interval plan

- Given the SAME level of respect and input

- Flowing without stops and restarts

Finally, if we look at how constraints and roadblocks are categorized between them from a focus standpoint, you will see:

SYSTEM DESIGN with first planners, project managers, and supers

- Constraints: First Planner System (Takt Production System)

- Working toward the SAME long-term plan

- Going the SAME direction

- Moving in the SAME sequence

- Providing the SAME amount of value (energy or effort) to each zone

- Receiving the SAME amount of work or value in each zone

- Going the SAME speed

- Being the SAME distance apart

- Constraints: Scrum

- Receiving all needed resources to perform the work on time

- Constraints: Scrum AND Last Planner System (LPS)

- Being on the SAME team

SYSTEM EXECUTION with last planners, foremen, lead persons, and supers

- Roadblocks: Last Planner System

- Working toward the SAME short interval plan

- Given the SAME level of respect and input

- Flowing without stops and restarts

As you can see, foremen will focus on roadblocks in last planner meetings and supers will focus on constraints in strategic planning meetings. Supers must focus mostly on system flow and the removal of constraints and ask foremen for help when needed. Foremen must focus mostly on the removal of roadblocks and ask supers for help when needed.

Reason 2: We need to know how to deal with both proper terms.

A constraint or bottleneck is something that shows up as a part of the system design—it is something the first planners focus on and adjust with the last planners. It will almost always show up in the way the site or the crews are organized.

A roadblock is something that shows up as a part of the execution of the plan by the last planners—it is something the last planners focus on and remove with the first planners. It will almost always show up in the form of something being in the way or a resource that is missing for the crew to perform the work in the area.

This is what we want our last planners focusing on. Sure, we also want them to know when the system design is constrained, but those discussions almost always happen with the general contractor and company leaders on the side and are not a focus of collaboration in our trade partner weekly tactical or daily huddle. So, let’s focus on a roadblock board in those meetings. It is the only one required for the last planner system. Constraints can only be managed and are managed by the Takt Production System in strategic meetings with input from last planners.

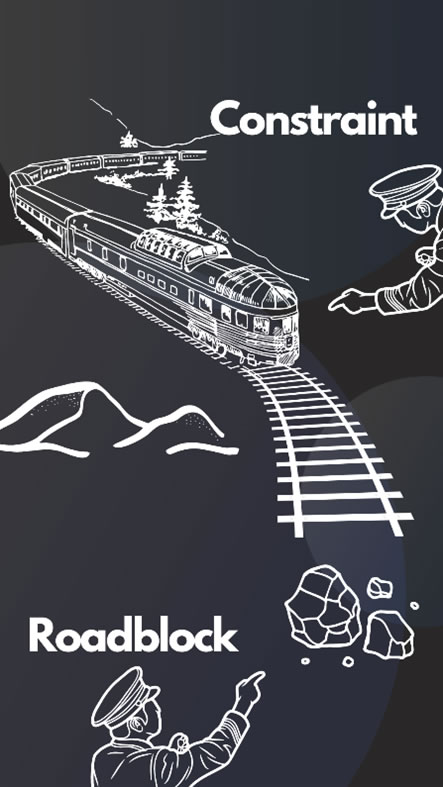

Reason 3: We need to keep the train and caravan analogies going.

The analogy of trains in construction is likely the best analogy available for how to implement Lean in construction. Construction works almost exactly like a rail-line. Crews are organized as trains, and trains of trades should have buffers between them like trains do between the cars. The rail lines symbolize the kind of preparation, leveling, and capacity needed for the train to flow.

And the term roadblock is perfect to symbolize something that the cowcatcher (a.k.a. that metal frame at the front of a train) should remove from the tracks ahead of the train. Mountains, valleys, rivers, or other features are constraints, and we build the tracks or roads around them. Additionally, the configuration of the tracks and the speed and efficiency of the train have constraints.

I once heard a quote that said, “Stand where you are and lift where you stand.” If we are to do this in construction, supers with foremen will manage constraints, and foremen with supers will find and help remove roadblocks. If we are to do this, our strategic meetings will focus on system design and how it is constrained, and our weekly planning meetings and daily huddles will focus on execution and the removal of roadblocks ahead.

It comes down to this:

- Constraints are for the production system design and adjustment; they are the main focus of supers.

- Roadblocks identification is to clear the path for that production system; this is the main focus of foremen.

Together, with these expanded definitions of terms and team roles, we can keep our train of trades on the track (and on track) and moving to the station—the completed construction project.