Unlock the potential of the Takt Production System for construction project planning. Optimize schedules and explore alternative options. Takt expert, Jason Schroeder explains.

Takt Production System

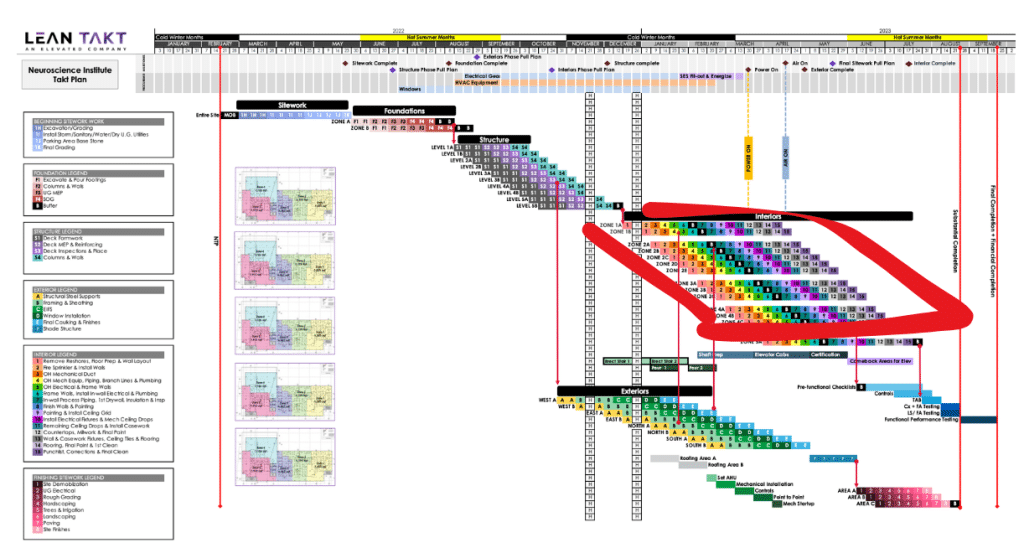

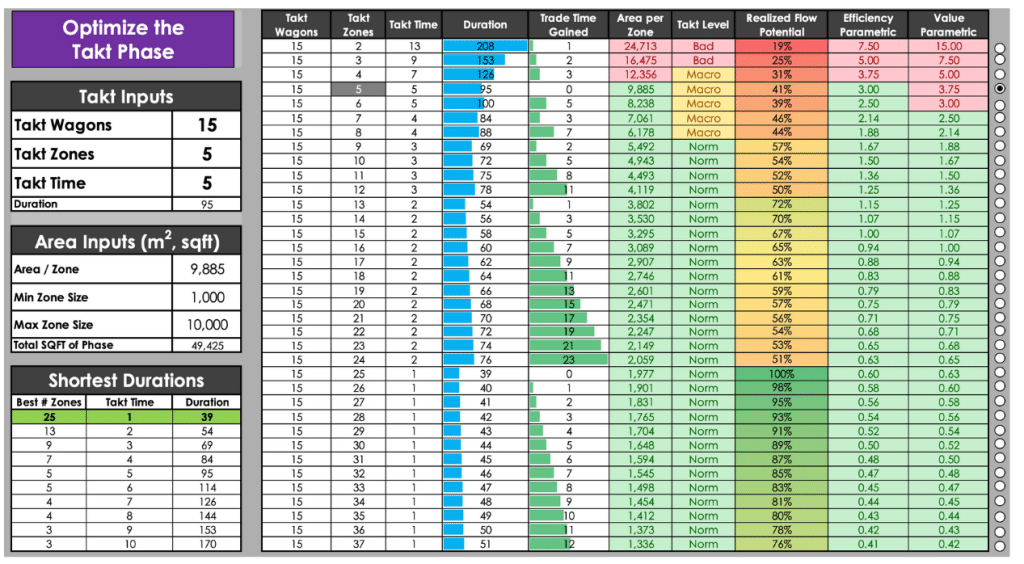

Did you know you can shorten phases by rezoning them and making zones smaller?

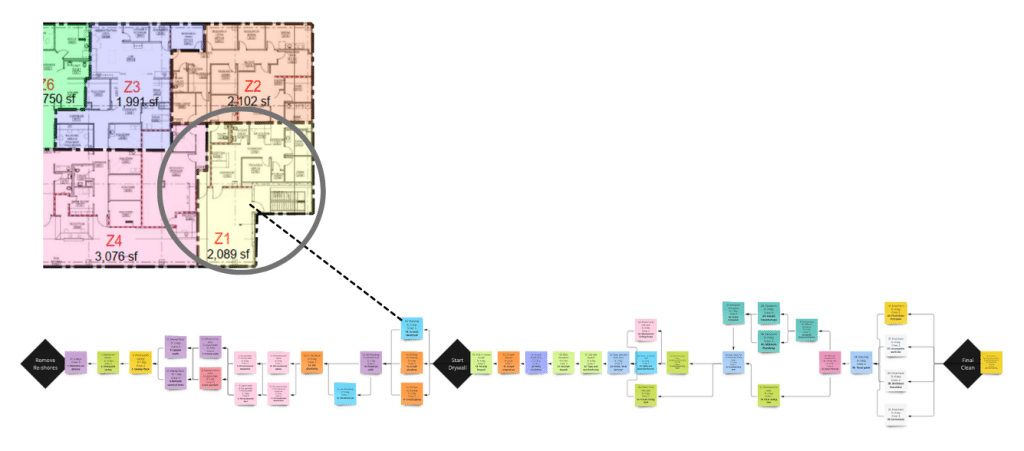

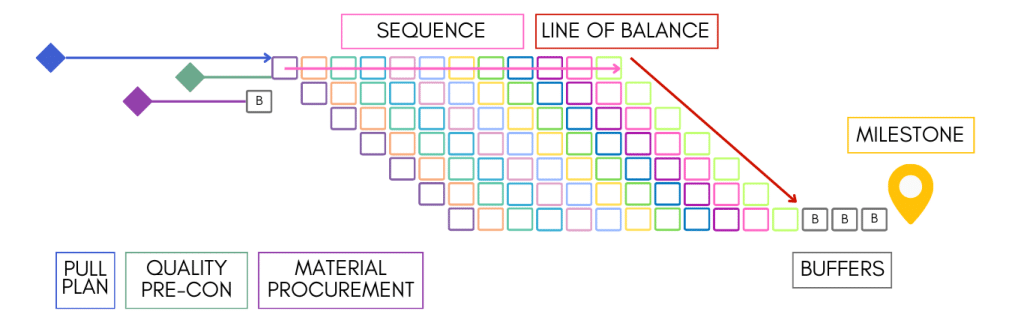

For instance, if you take this 7-zone phase shown below and double the zones—which decreases their actual size by half—you gain quite a bit of time on the schedule. And here is the best part: it NEVER hurts or overburdens trades.

This is handy when creating project production plans because you can show the owner other possible options for the project. This is different from typical construction master schedules.

Takt plans are simulated production plans showing what is possible as a target. This then provides a rhythm and visual plan that can be adjusted.

Typical CPM schedules are wish lists predicting when activities will happen compared to a baseline. Because it does not simulate what is possible, it is useless (in my humble opinion).

Smaller zones mean the trades can go faster.

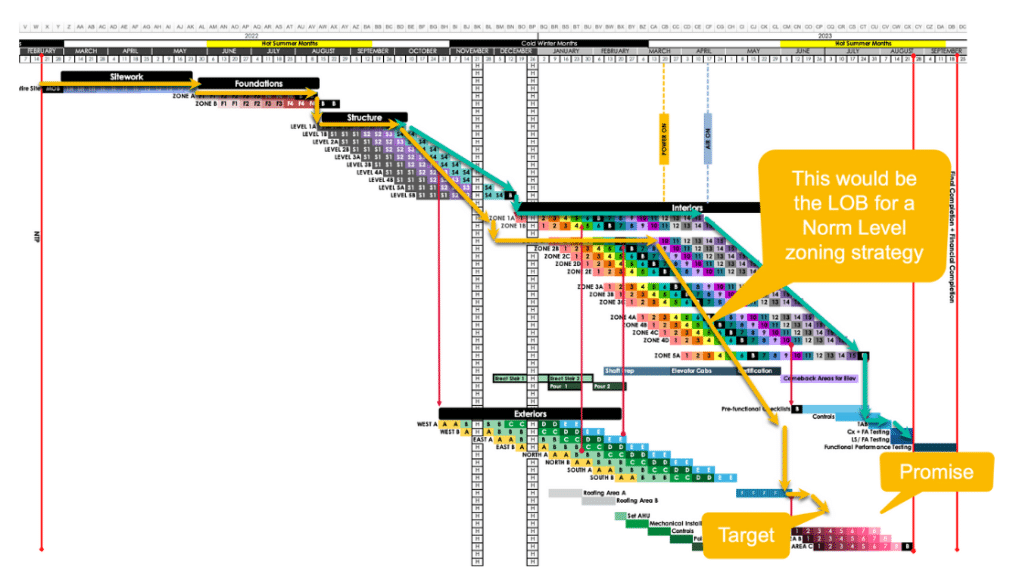

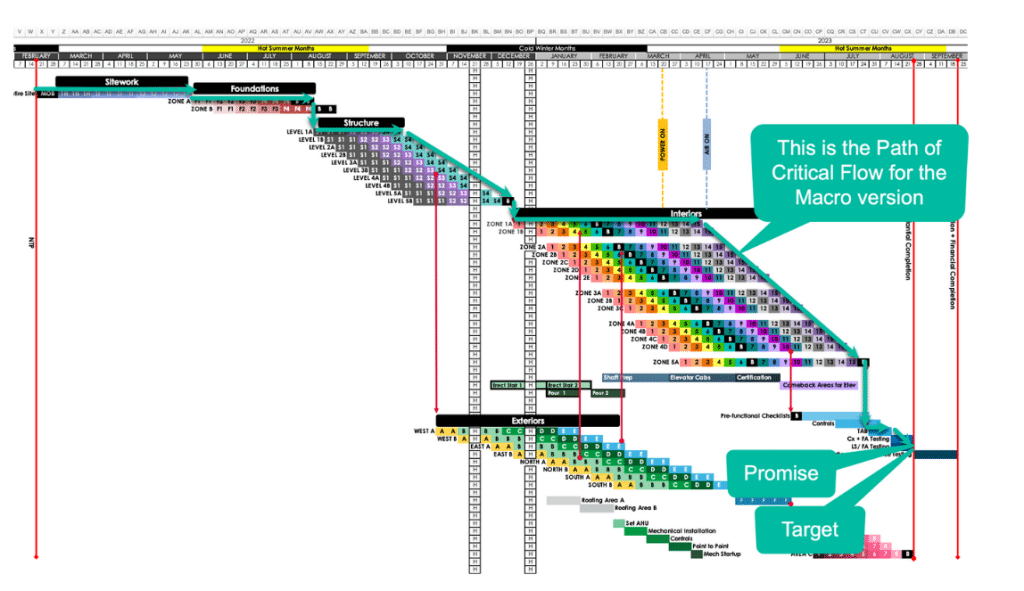

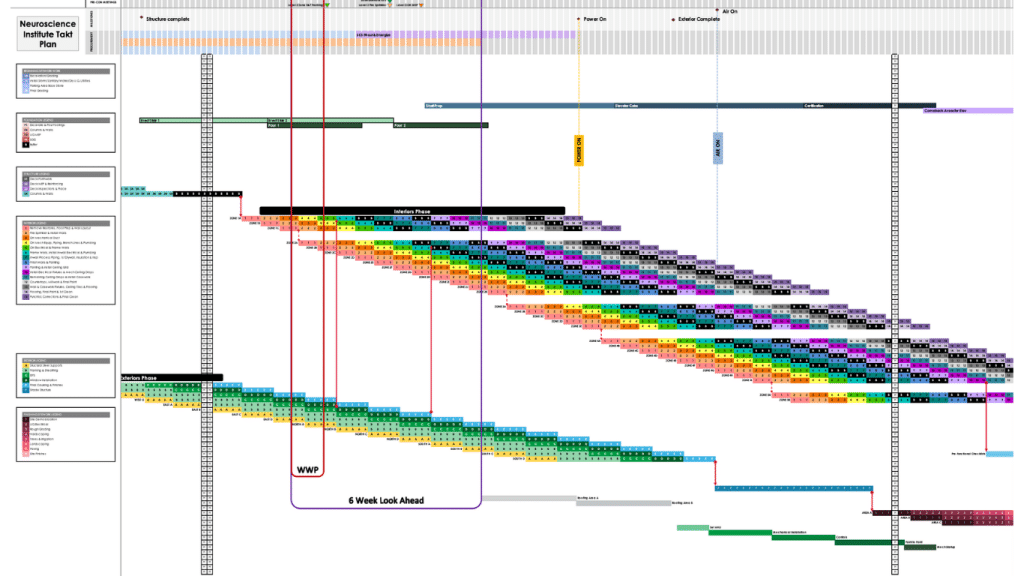

So, Takt planning allows you to target three different speeds without ever affecting your trades negatively or spending more money. The Macro strategy (your promise), your norm (your target), and your backup. The image below shows a Macro schedule.

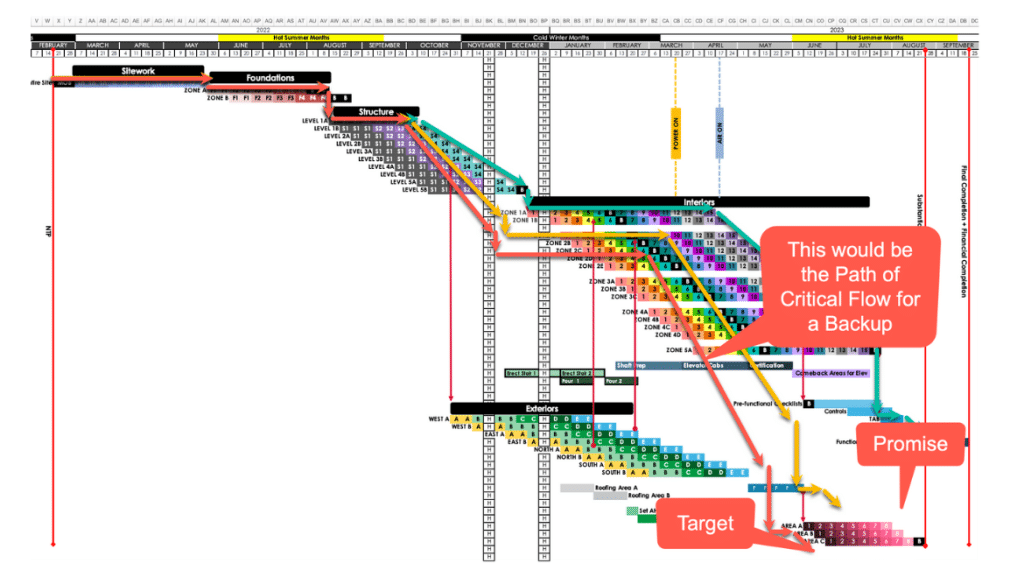

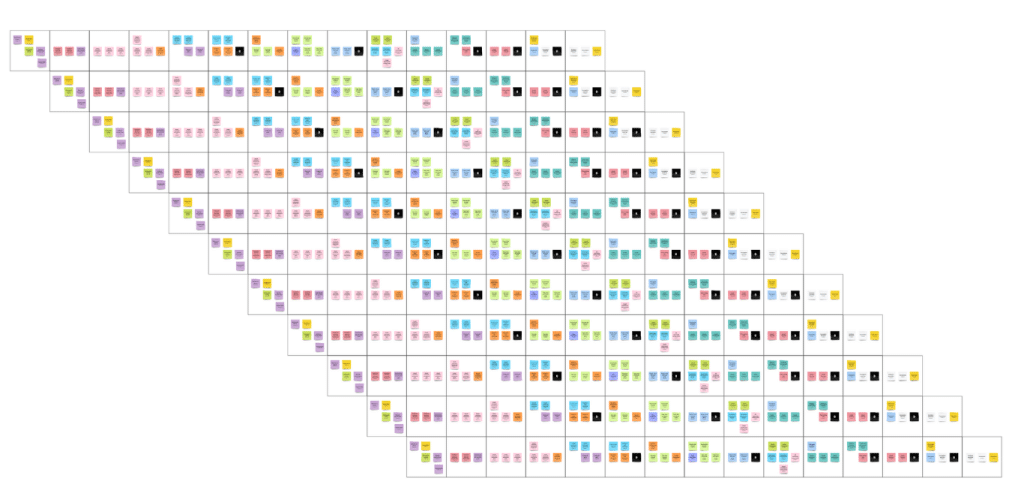

As you can see below, the schedule can be pulled back quite a bit just by rezoning. The only thing to remember is that your team will need buffers at the end of your phases, so you cannot give away all the time gained to the owner. You must leave two-thirds of the time gained for buffers in the schedule.

And keep in mind you will always want a backup zoning strategy in case your project ever gets in trouble.

Takt Production System Strategies

You can identify your various strategies by using the Takt Production System and the Little’s Law Calculator (found on www.leantakt.com) made by Kevin Rice and informed by Marco Binninger and Janosch Dlouhy.

When you have a Macro-level Takt plan, you now have your promise date for the owner and the contract.

We then log the number of wagons and zones into the calculator to find out how many zones we would need for an ideal Norm-level schedule.

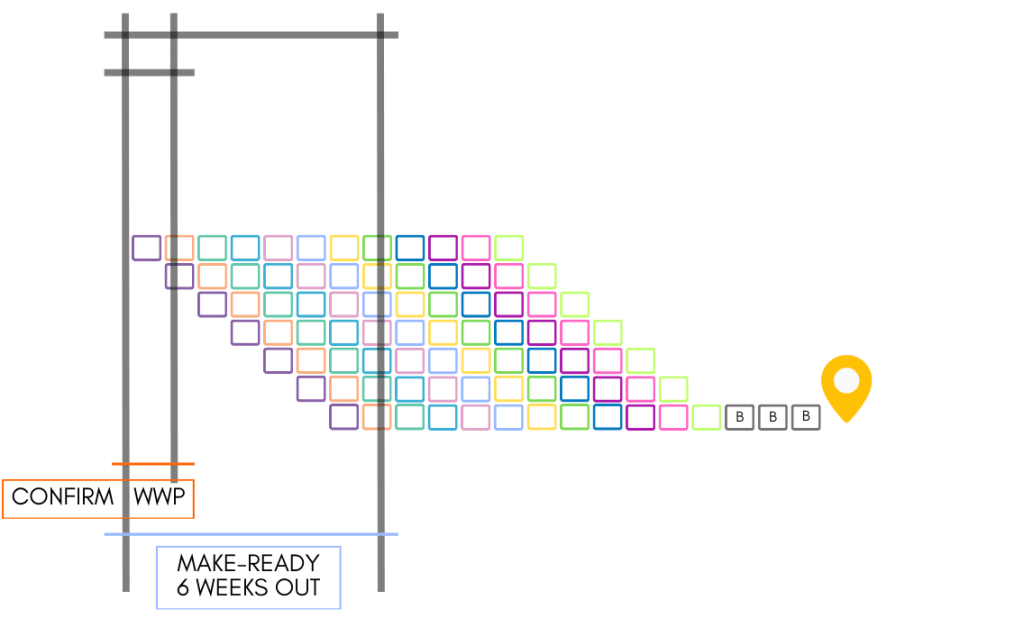

If you now know the ideal number of zones for your Norm-level schedule, you can make your zone maps reflect your new number of zones according to your work density analysis and start pull planning your first representative zone.

When you pull plan, you only pull plan that one zone and then do a stacking comparison according to the rhythm of the Takt time stagger.

Once you have confirmed you have trade flow, you can transform your stacking comparison into a full-blown Norm-level Takt plan.

Your Norm-level schedule will be the production-level schedule that represents the target for you and your trades. You will filter your look-ahead and weekly work plan directly from this schedule.

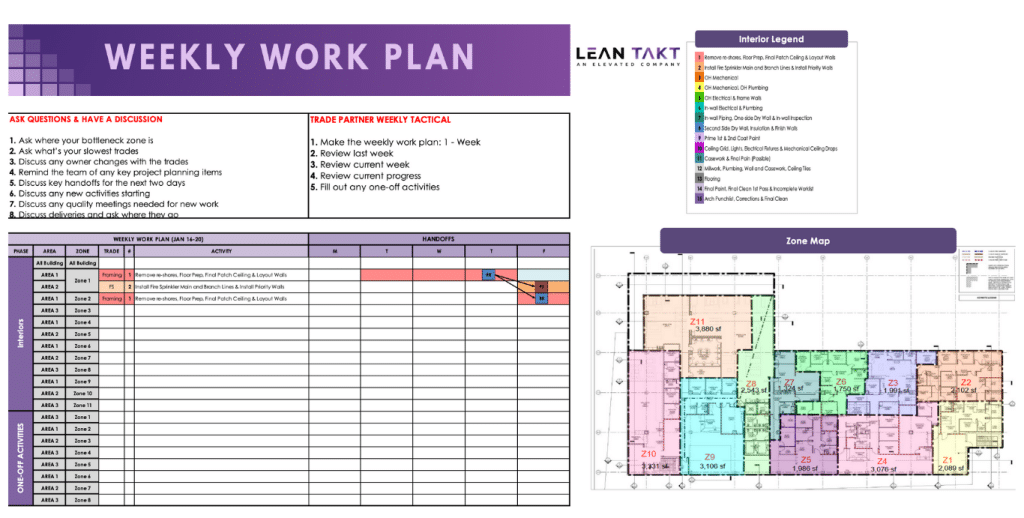

The weekly work plan is filtered from the Norm-level Takt plan and is complemented with sub-tasks and handoff indicators. It is all in a flow and vertically aligned.

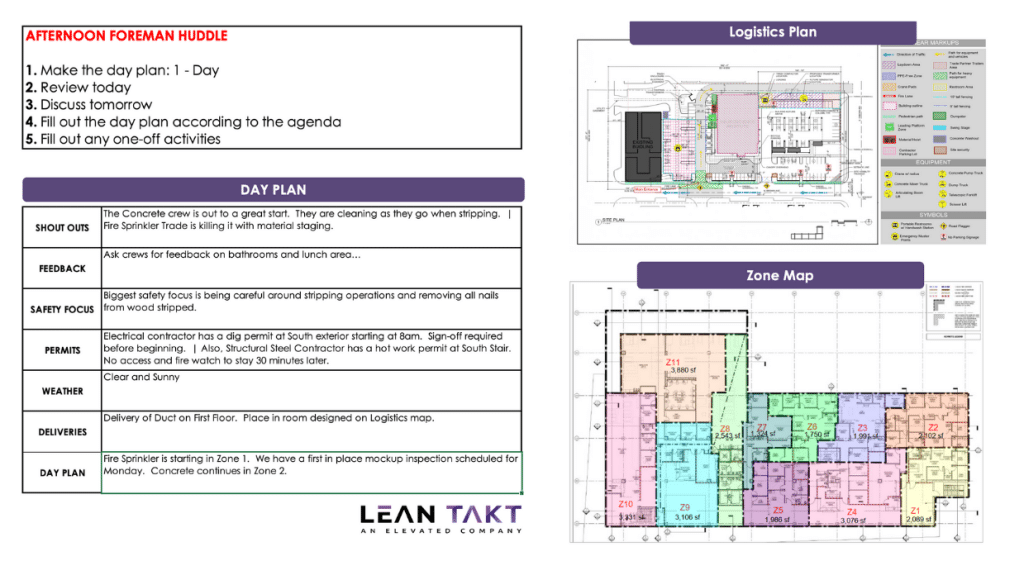

The day plan is then created from the weekly work plan and formatted in a way that can be easily communicated to workers the next day. This will be the outcome of coordination, collaboration, and commitment among the Last Planners on your team.

As the trades execute in the field, certain KPIs are tracked so the team can see how they are performing. Key KPIs include:

- Percent Planned Complete: percent of promised items on the weekly work plan executed as promised. Target is >80%.

- Percent Handoff: percent of handoffs on the Takt plan accomplished successfully. Target is >80%.

- Remaining Buffer Ratio: ratio between remaining buffers and the amount needed to finish the project. Target is >1.

- Roadblock Removal Average: average days before impact that roadblocks are removed in that functional area.

So, as you can see, we control the sequences, line of balance, buffers, and milestones at the Macro and Norm levels. This schedule triggers the need for pull plans, quality pre-con meetings, and material procurement.

This base then allows you and the team to easily filter the 6-week make-ready look-ahead plans for making work ready and removing roadblocks. Additionally, the weekly work plan is filtered here and adjusted by trade partners for commitment in the weekly trade meeting.

As we put it all together, we see:

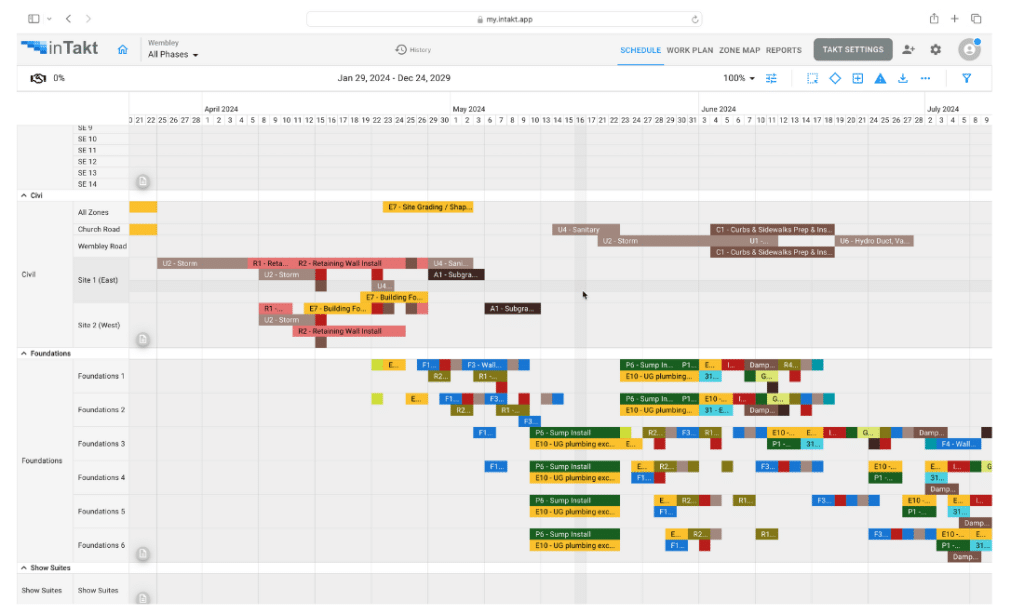

- Macro-level Takt plans are used in pre-construction efforts to visualize the plan, create a project strategy, and then verify the overall project duration target.

- Norm-level Takt schedules are made from pull plans and used for production on-site and managing the production system.

- From this stage, you can filter your Last Planner tools and export to CPM if needed.

- The 6-Week Make-Ready Look-Ahead plan is automatically filtered from the Norm-level schedule and provides a view that trades can use to make work ready and remove roadblocks ahead of the work.

- The Weekly Work Plan is further filtered down from the Norm-level Takt plan and represents the schedule that the trades will adjust and commit to for the next week. This is the commitment-level schedule that trades will execute in the field.

- The Day Plan is made in the Daily Huddle and provides the foremen and workers with a highly visible plan they can follow in the field.

- With the Day Plan in hand and well communicated in the Daily Huddle, foremen and workers can now fill out their safety and quality Pre-Task Plans.

- As work is completed, the Percent Planned Complete (PPC) is tracked and calculated along with Variances that enable improvement.

All of this can be done in software that automatically exports a CPM schedule from the production plan.

We do not create schedules per se in Lean Construction. We create production plans.

In my view, you can either coordinate your Last Planner work from a wish list or with a simulated production view. The choice is becoming clear and scaling fast throughout the industry. I know what I’d choose.