The Last Planner System® (LPS) is a collaborative scheduling system that uses the wisdom of trade foremen, called last planners, to create reliable promises that can be executed in the field with a high level of certainty. At its core is the concept of Respect for People and leveraging The Wisdom of the Team. The Last Planner System has been used with great effect on projects which is resulting in higher engagement, shorter durations, and higher profits.

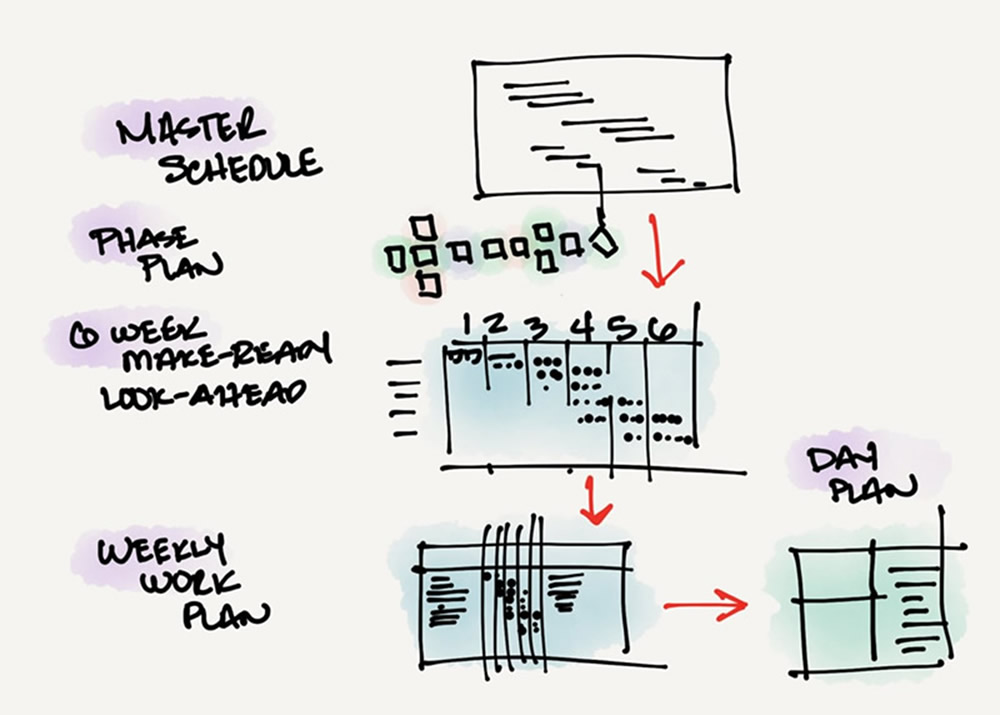

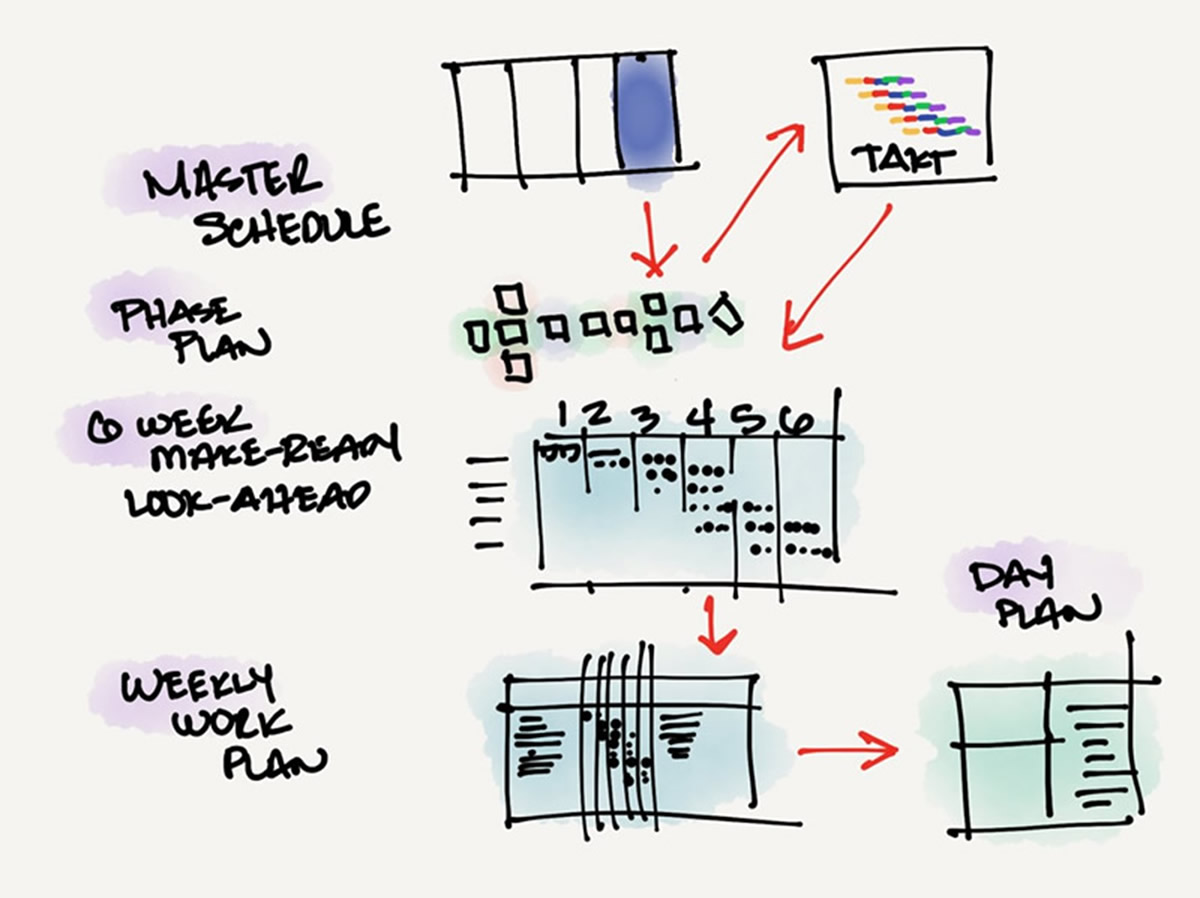

The Last Planner structure in its basic form includes the following schedule processes and formats:

- The Master Schedule – The process of creating a master schedule should enable the project team to identify an accurate overall total project duration and project milestones.

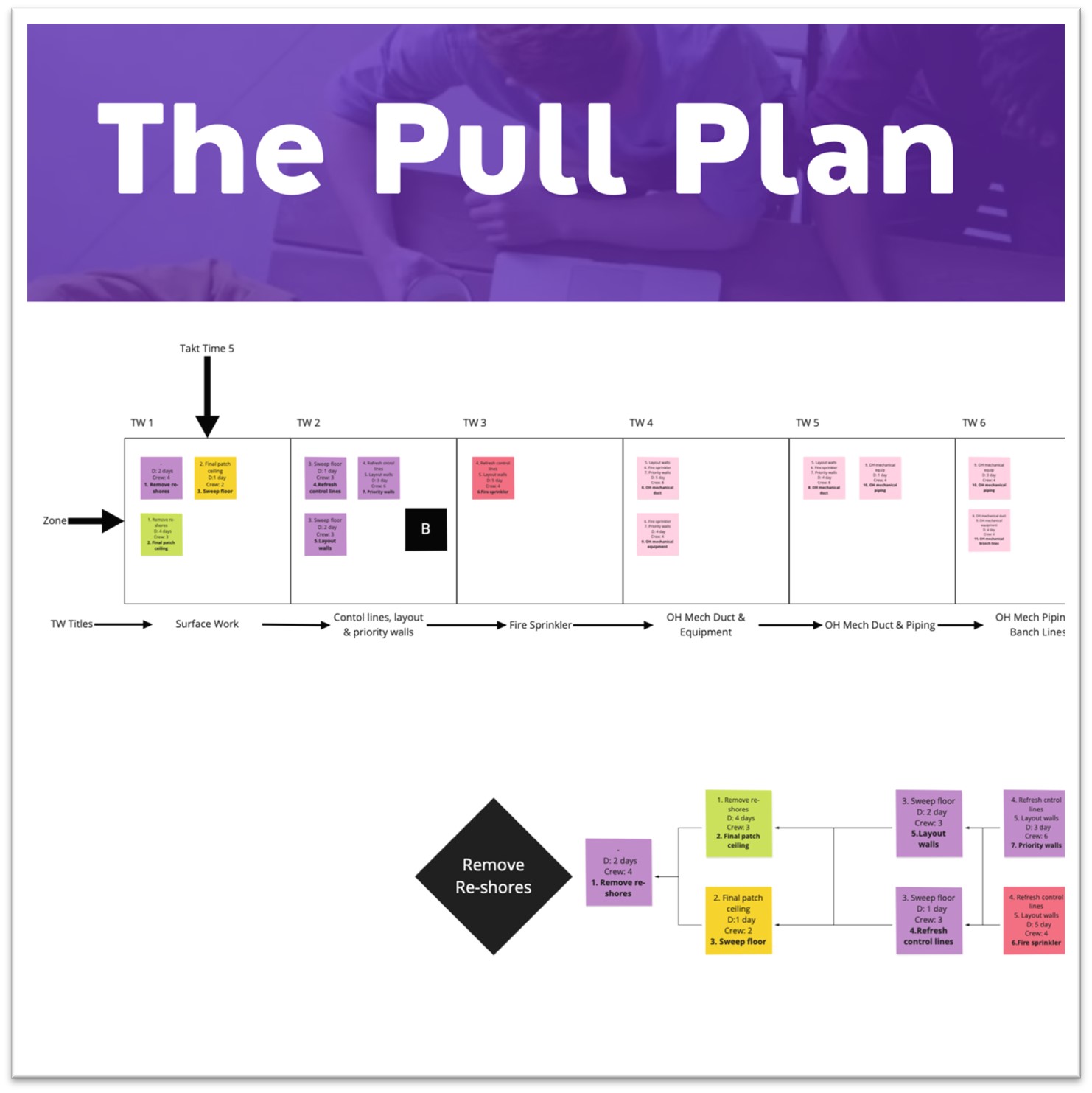

- The Pull Plan – The process of engaging trade partners in the process of pull planning is to become a collaborative team, identify the proper sequence for a phase, and identify accurate durations and handoffs.

- The Look Ahead – The process of creating and reviewing a look-ahead schedule is to look ahead as a team and make work ready. As work is made ready with labor, materials, equipment, tools, permissions, layout, and information, possible roadblocks will emerge and become visible to the team. The outcome of this process and format is to align resources to the committed dates, make work ready, and clear roadblocks so work can be performed without stops and restarts.

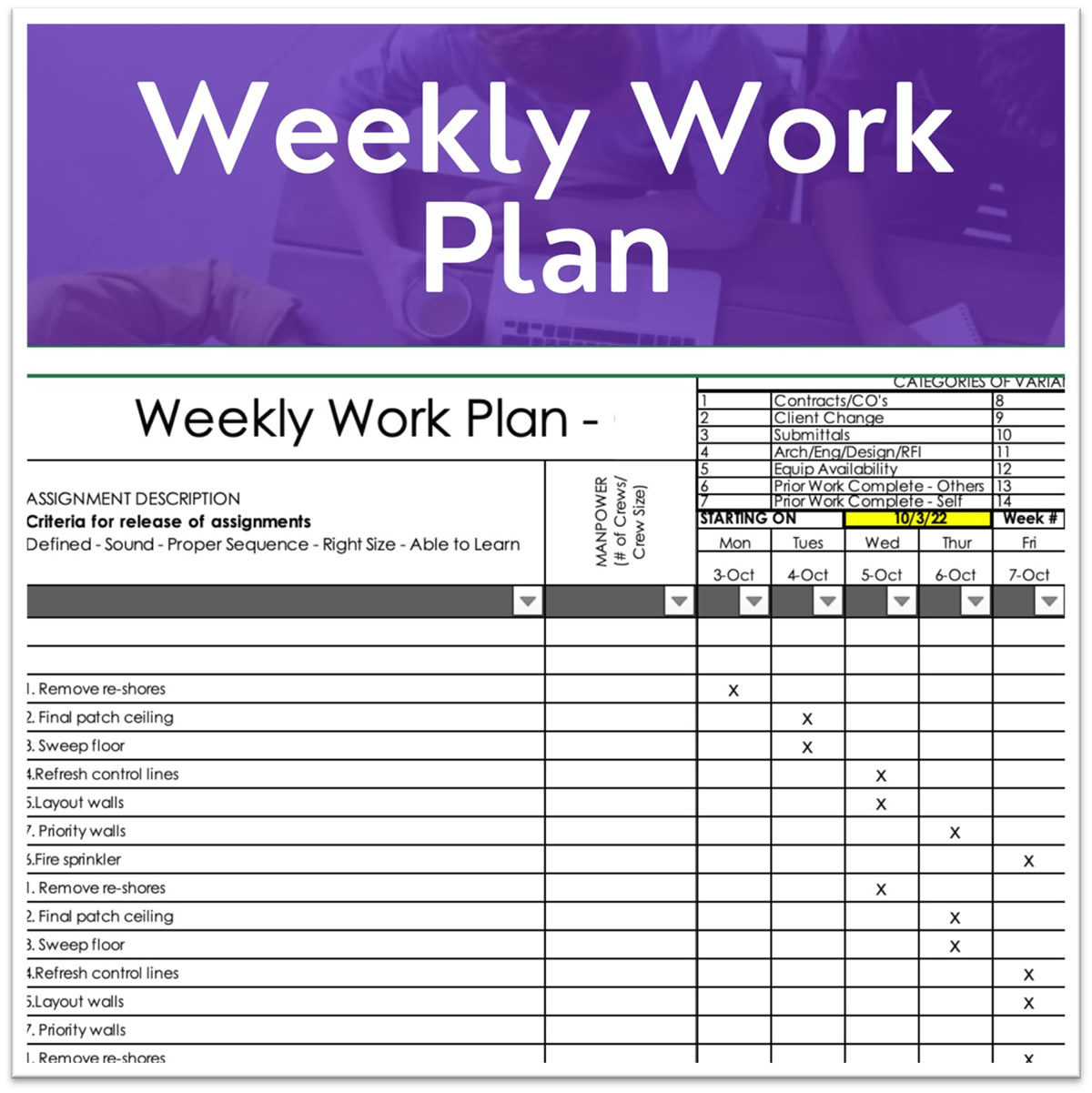

- The Weekly Work Plan – The process of creating a weekly work plan is to involve all trade partners not only in the identification of the sequence and durations of the work, but also the planning of the work on exact dates within the week. The last planners and superintendents collaborate, commit, and create a flowable work plan that can be executed with certainty.

- The Day Plan – The day plan is the executable plan for the day that the team completes the day before or the morning of the work. This plan enables all specifics for the day to be understood and carried out by the team because they have planned and committed to HOW they will execute the work together as a team.

- Percent Promises Complete (PPC) – The process of tracking the number of promises made as compared to how many were kept on a daily and weekly basis is to identify a percentage the team can use to track their success. Historically projects that keep over 80% of their promises from weekly work plans are on or under budget and on schedule. Tracking promises missed also triggers the team to do a root cause analysis on why the promise was not met so the team can take corrective action in the future.

Here is a video that takes a deeper dive into The Last Planner System:

I have wildly oversimplified the system for the purpose of making a point. This is a great system, but as with all Lean systems, it is time for us to use the PDCA cycle (Plan, Do, Check, Adjust). It’s time for us to develop version 2.0.

The Problems Integrating Last Planner & Critical Path Method

So, let’s first understand the problem with Last Planner 1.0 based on a Critical Path Method (CPM) schedule:

- Problem 1: CPM schedules, without also tracking and monitoring trade flow and buffers in a visual way, will not produce a schedule with an accurate overall total project duration. We cannot forget that no schedule will be reliable, have an accurate critical path, or provide proper milestones unless each phase has trade flow and unless each phase (plus the overall schedule) includes buffers. This means the Last Planner System is relying on end dates and milestones that are incorrect.

- Problem 2: CPM milestones are batched, meaning they are based on larger zones or areas which 98% of the time are simply a guess by the team. Therefore, the milestones that are pulled to them are not only inefficient, but they are also out of place on the timescale and group too much work in areas that are too large. It also wastes the project team’s time and effort in creating the collaborative sequence because it is not optimized and does not enable flow. So, the pull plans are not accurate, reliable, and, even if they improve the schedule, they are still batched and inefficient overall.

- Problem 3: Because the master schedule is inaccurate, it will never align with what is happening on the project. So, the look-ahead schedule, weekly work plan, and day plans will become a hybrid of what is happening and what the team wants to happen. It will drift enough in the timescale to effectively disconnect the procurement-effort targets from the short-interval targets. This results in last planners wanting to commit to the look ahead and weekly work plan but not being able to because the supply chain is unable to provide the information and resources to accomplish the promises.

- Problem 4: Because it is so time consuming and problematic to update a typical CPM schedule, the team is either slowed down when refining sequences with the pull plans or they decide to detach the pull plan, look ahead, and weekly work plan from the master schedule. When this happens, it becomes very difficult to see that these are vertically aligned. Once this cannot be seen, we end up with separate schedules in separate formats that confuse the team. Additionally, the CPM schedule is not a schedule that anyone on the project can see or understand, so no one is ever able to see how short-term decisions affect the long-term plan with certainty.

- Problem 5: Because the current master schedule method with CPM does not create reputable work through zones, the weekly work plan must be made from whole cloth every week. This overburdens the foremen, who most of the time are guessing what we want and making assumptions that are not integrated well with the team. They must spend hours every week preparing work plans. In fact, this leads to most projects over $20 to $40 million abandoning the Last Planner System during complex phases because the weekly work planning process, combined with pull planning, overburdens the team. It pulls them away from leading the project.

- Problem 6: Because there is little focus on trade flow in the industry’s current scheduling systems, the weekly work plans and day plans end up stacked and burdened. That means too many trades working in one area, and trades working in too many areas all at once. The problem with this is that it’s not possible. So, the master schedule, look ahead, weekly work, and day plans lie to the project team by enabling them to set impossible targets.

- Problem 7: Because targets are not real and every task on the plan is run as an independent and individual play, the PPC is not tracking anything that can be repeated and improved. That means the PPC score will not only be inaccurate, but it will not help the team make improvements because tasks are not designed to repeat.

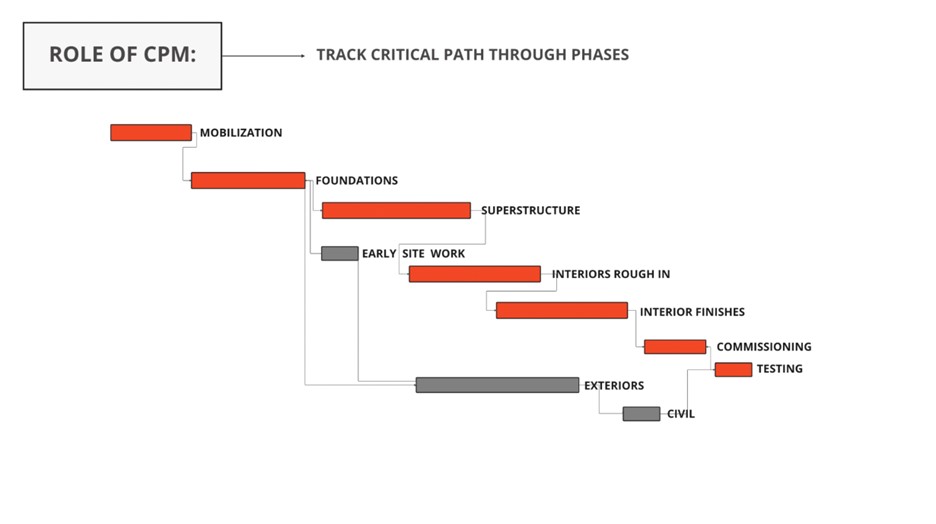

I realize full well that this may seem critical of CPM and may appear off-putting. Let me try to win you over a bit by saying that I do believe we can merge Takt and CPM methodologies — if CPM begins to track phase summaries and stays at a high level. If that was to happen, the CPM schedule would track a critical flow path through phases and begin to track real data. But make no mistake about the fact that Takt must govern the phases and Last Planner must govern the short interval with Takt.

And even if someone was offput by my earlier list of seven problems, I don’t believe anyone could deny these seven things happen almost every day on construction projects throughout the world. So, let’s ask ourselves why.

May I give my opinion?

We Need Last Planner 2.0.

So, what is Last Planner 2.0? Here is a list of the improvements that I would make immediately to the system to create Last Planner 2.0:

Step 1: I would make CPM manage only Phases & Sequences.

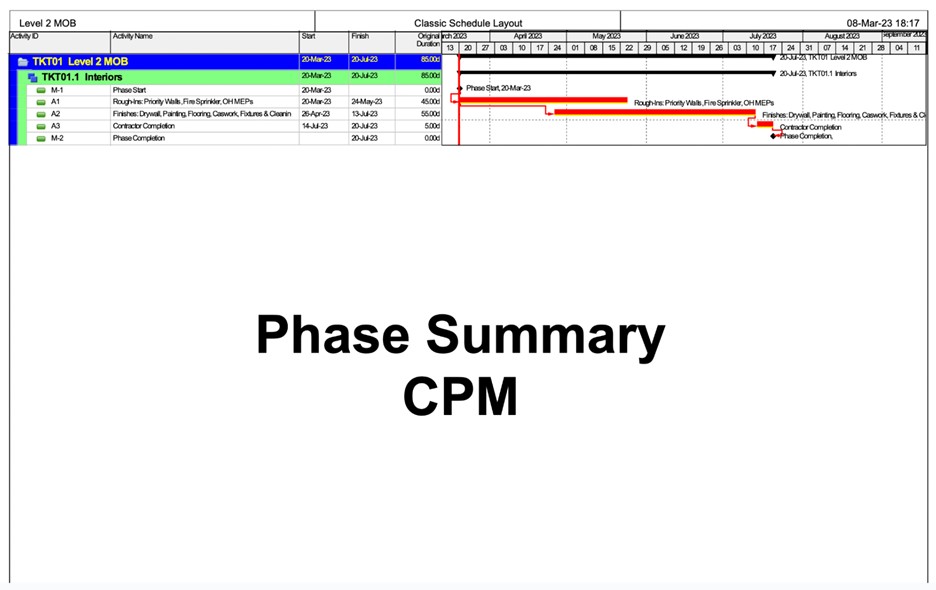

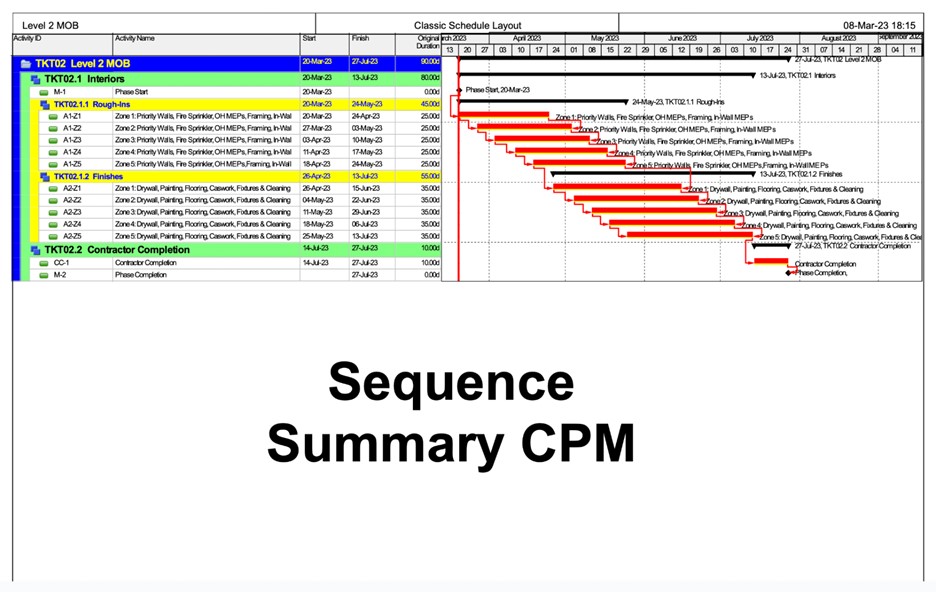

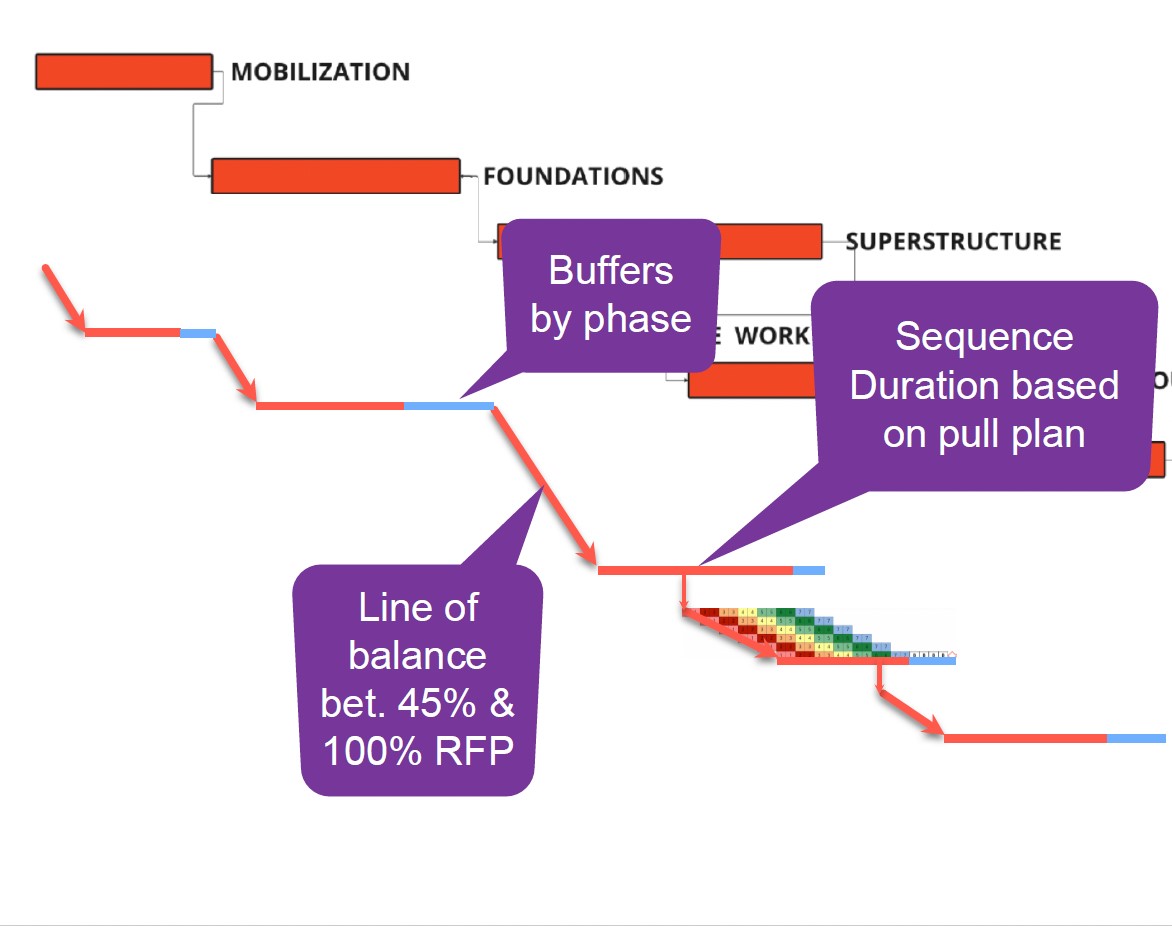

If CPM is a contract requirement that cannot be negotiated, transition CPM to be a level 2 schedule that only summarizes phases and sequences. CPM as a system was designed to be very high level and track the critical path through phases and sequences only anyway. This can be done by summarizing the phases or the sequences that are governed by Takt on a Takt rhythm.

It can summarize them as phases.

And it can summarize them as sequences.

The phase and sequence summaries would include buffers, respect the line of balance of the phase, and always have a rhythm that supported trade flow or confirmed separate resources for any stacking of activities, but it would never show level 3, 4, or 5 detail—it would only show the summaries.

The Takt plan would show the sequences, zones, buffers, and trade flow with the phase or simply represent a single sequence itself.

So, essentially, your schedule would be based on Takt and be summarized in CPM (if necessary), and the critical path would identify which phases and individual sequences were critical to the project.

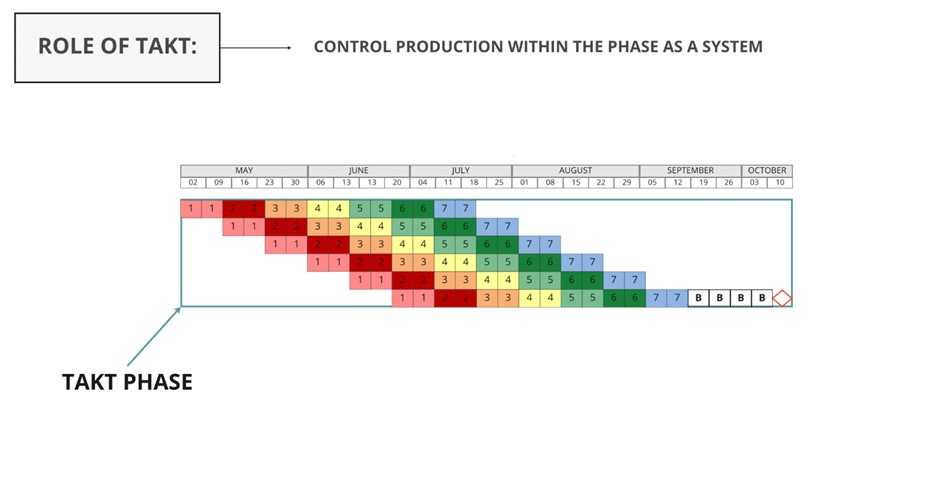

Step 2: I would manage the phases with Takt and Last Planner.

In Pre-construction, Takt plans would be created to govern the project and any work breakdown structures in CPM would mimic the Takt format. Additionally, every phase would be governed by a Takt plan for the macro, norm, and short-interval planning.

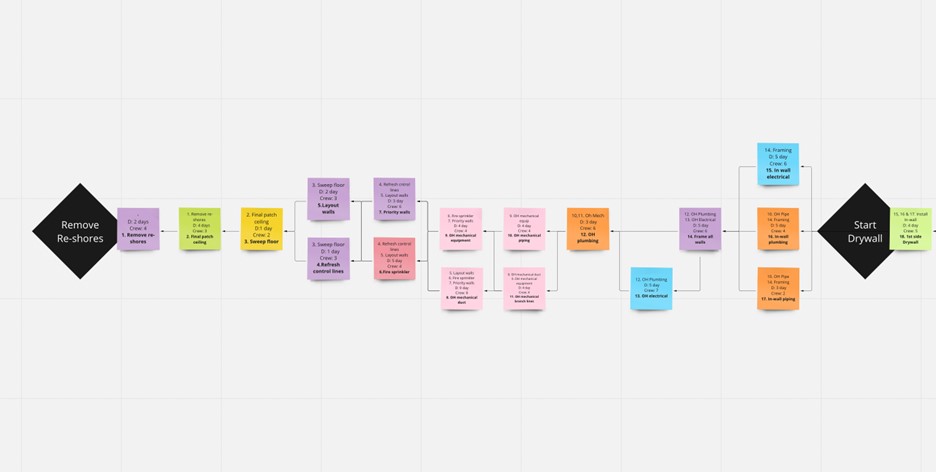

Step 3: All pull plans would be leveled and optimized with Little’s Law, so the phase can flow properly.

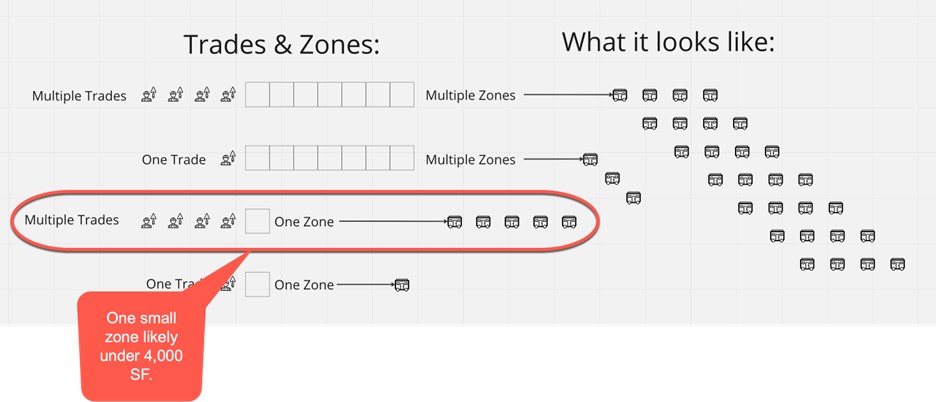

You see, a pull plan should never be alone and be done for an entire area or building, unless there is truly only one small zone likely less than 4,000SF. Pull plans are sequences for individual zones only throughout a phase. A Takt plan is simply a visual representation of pull plans properly packaged and stacked on top of each other. That means we need to do more with pull plans than we currently do:

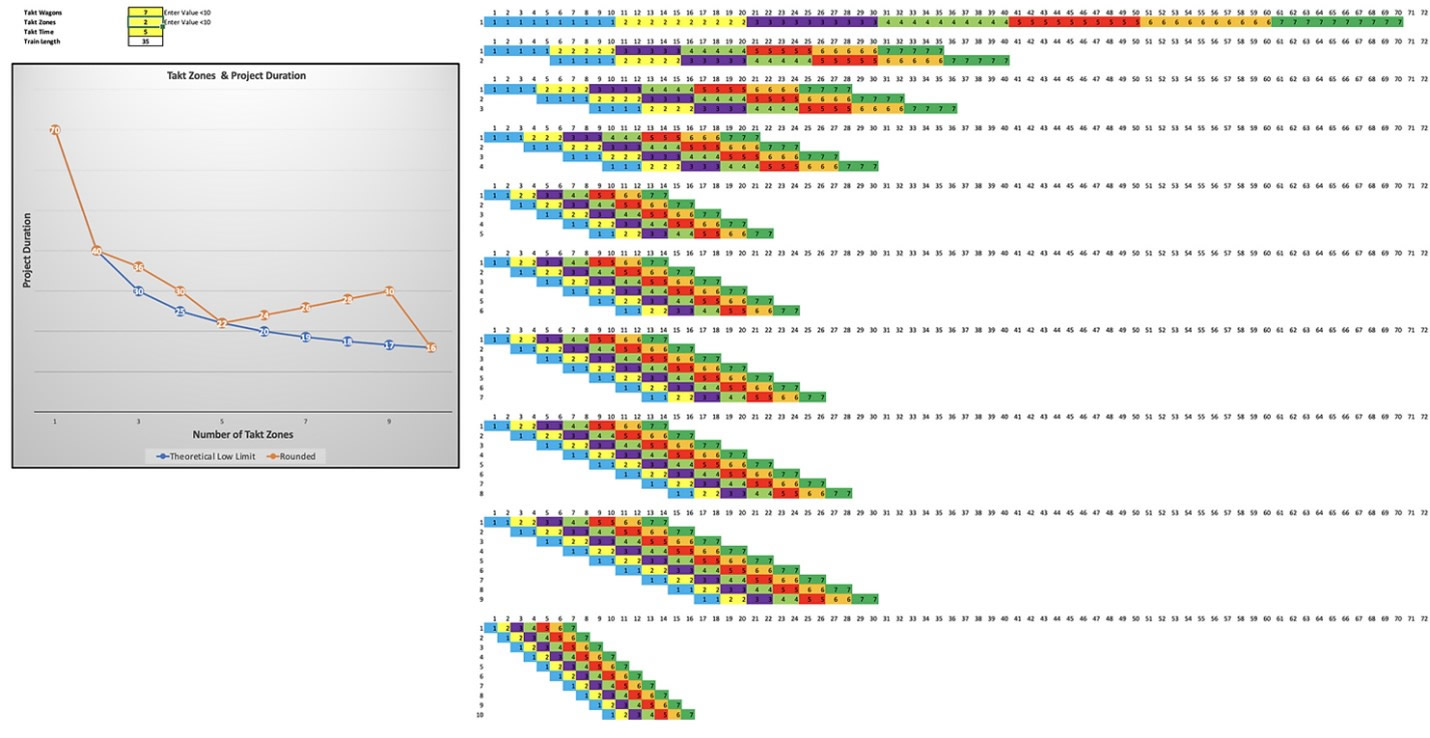

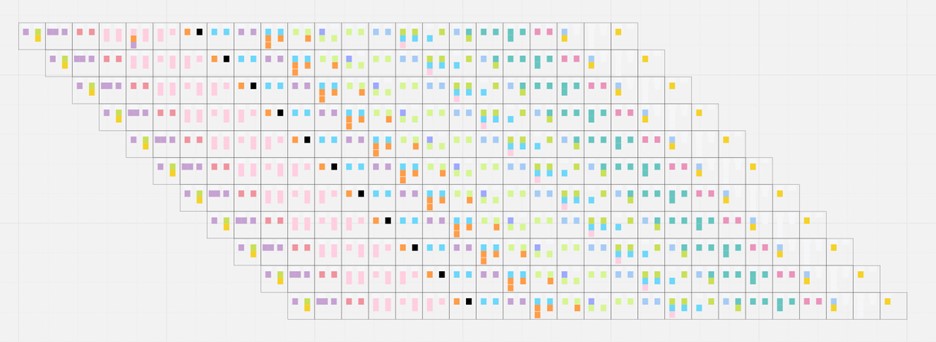

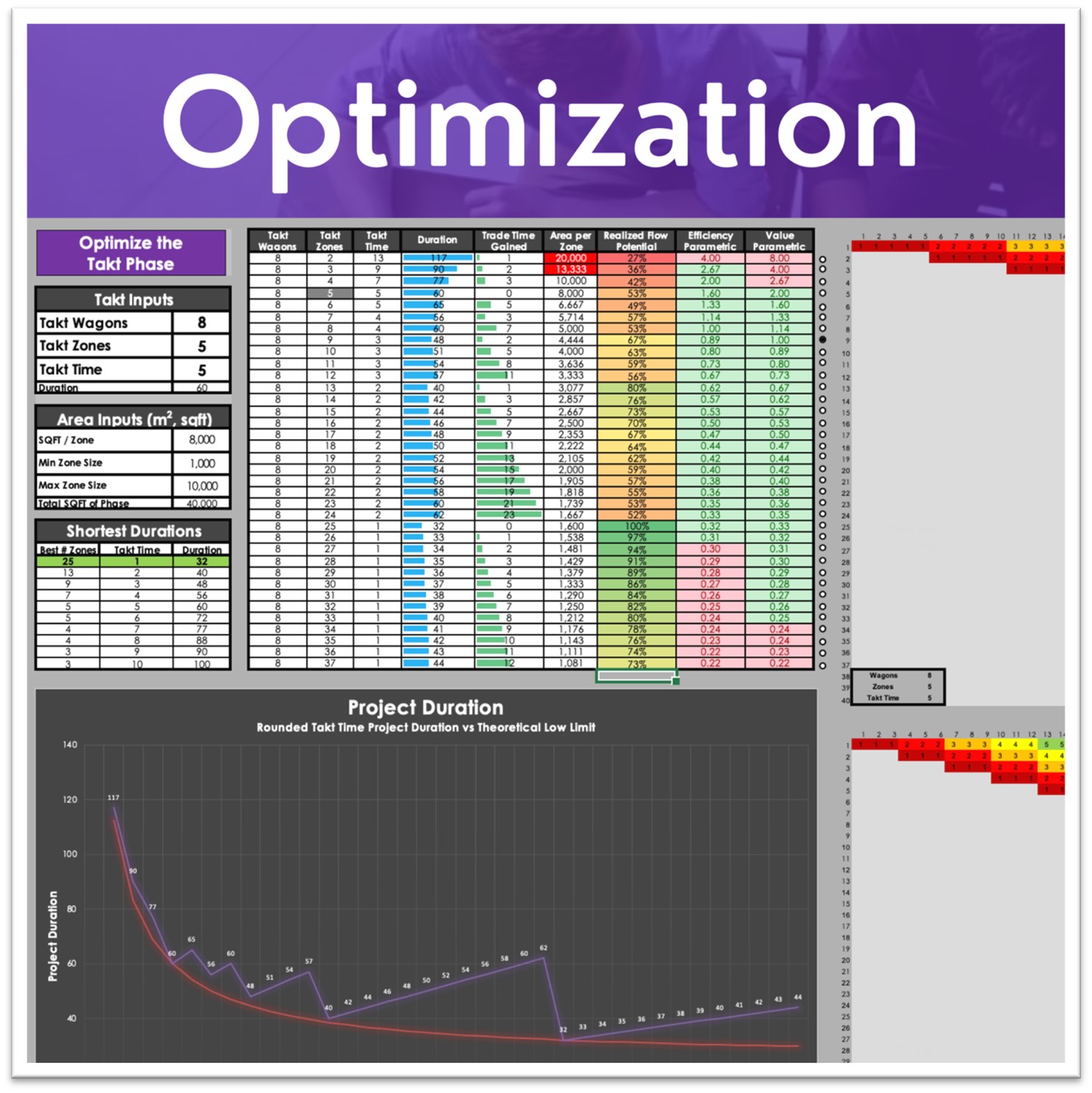

- We must make sure we know how many zones we should have. Remember, the smaller the zones, the faster you typically go. As you can see in the image below, schedules speed up or slow down based on how many zones you have.

- We must package your pull plan into Takts that represent Takt time by Zone.

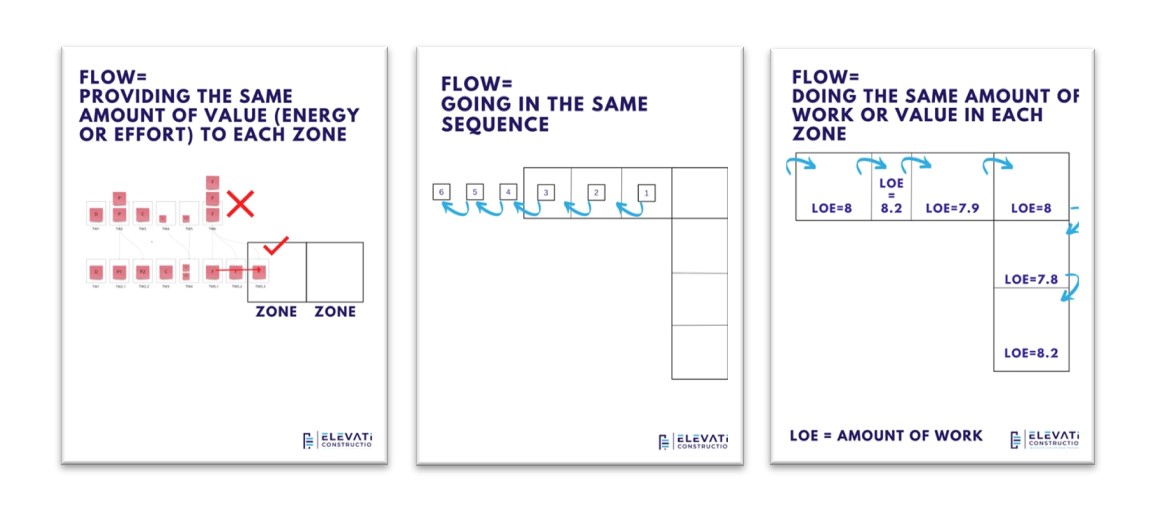

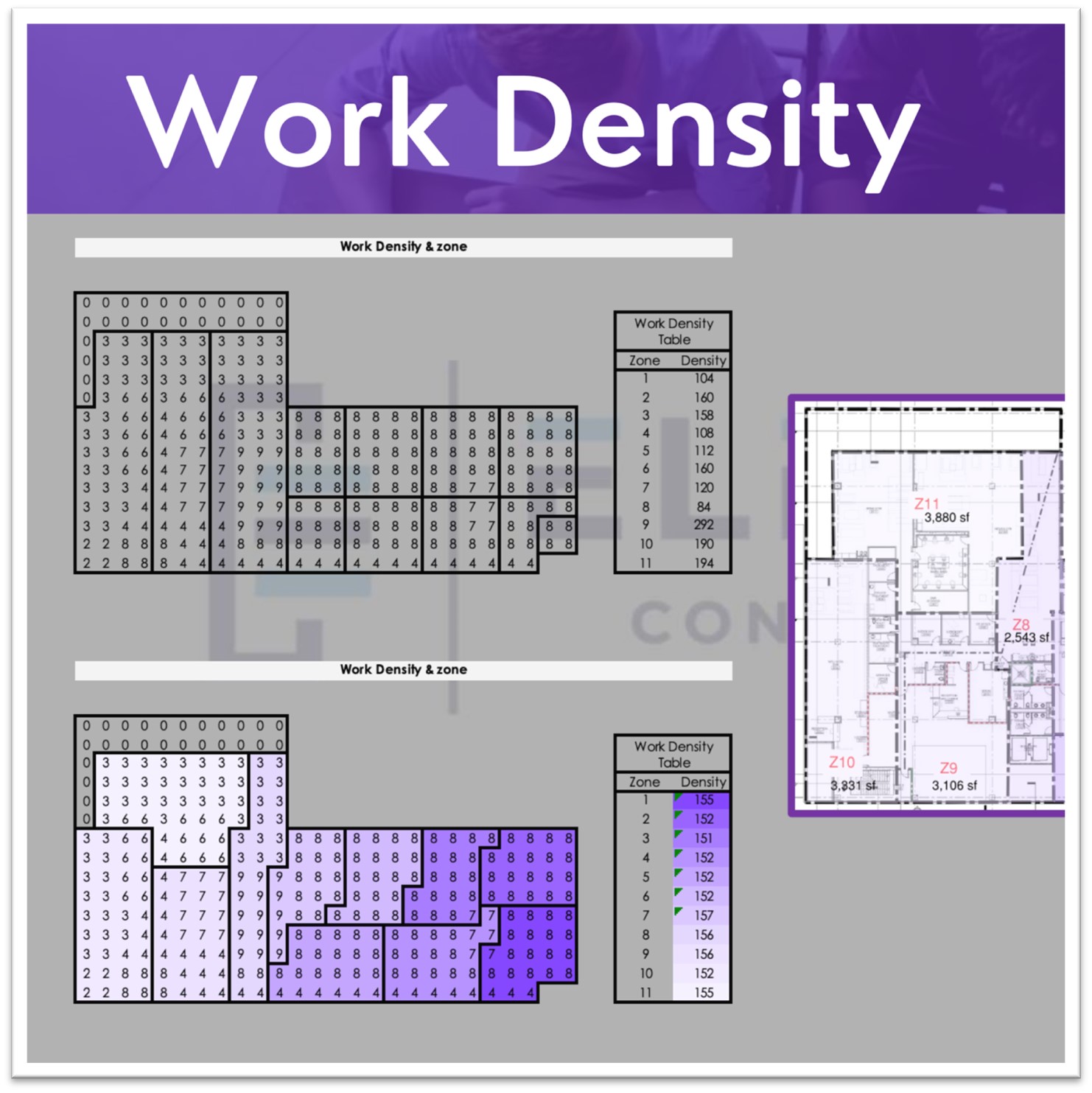

- We must level your zones by packaging work into a Takt sequence and leveling the zones to have the same amount of work in each zone.

If you remember from the last blog post, this enables your train of trades to go the same speed the same distance apart which is the basis for flow.

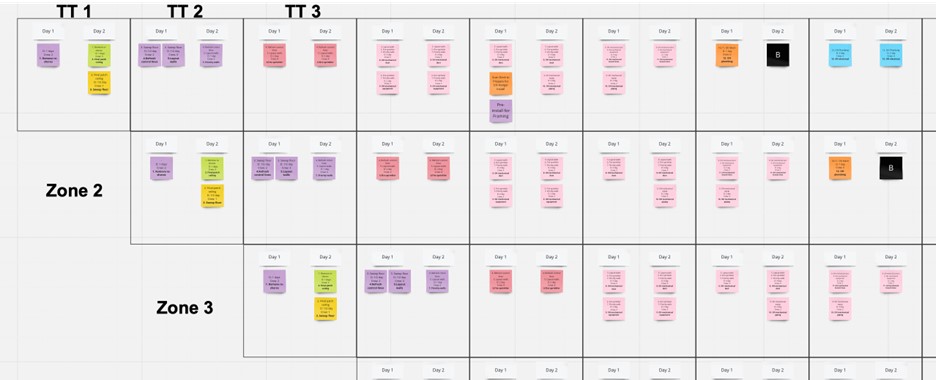

So, you would very rarely see a pull plan like this alone:

It would be packaged by zone like this:

In the image below, you will notice that you only see a pull plan by itself if you truly only have one zone. If you have multiple zones and multiple trades, you will need to see that pull plan formatted as a Takt plan.

You should rarely ever see a pull plan alone. A pull plan only represents one zone, and therefore, should always be shown on top of a duplicate pull plan in a Takt format if the square footage is more than 4,000SF. If this does not happen, the area will be batched, and you will be throwing away time and money needlessly.

How Last Planner 2.0 Would Work.

In LPS 2.0 you would follow this process:

- Identify the phases for the project as they relate to trains of trades.

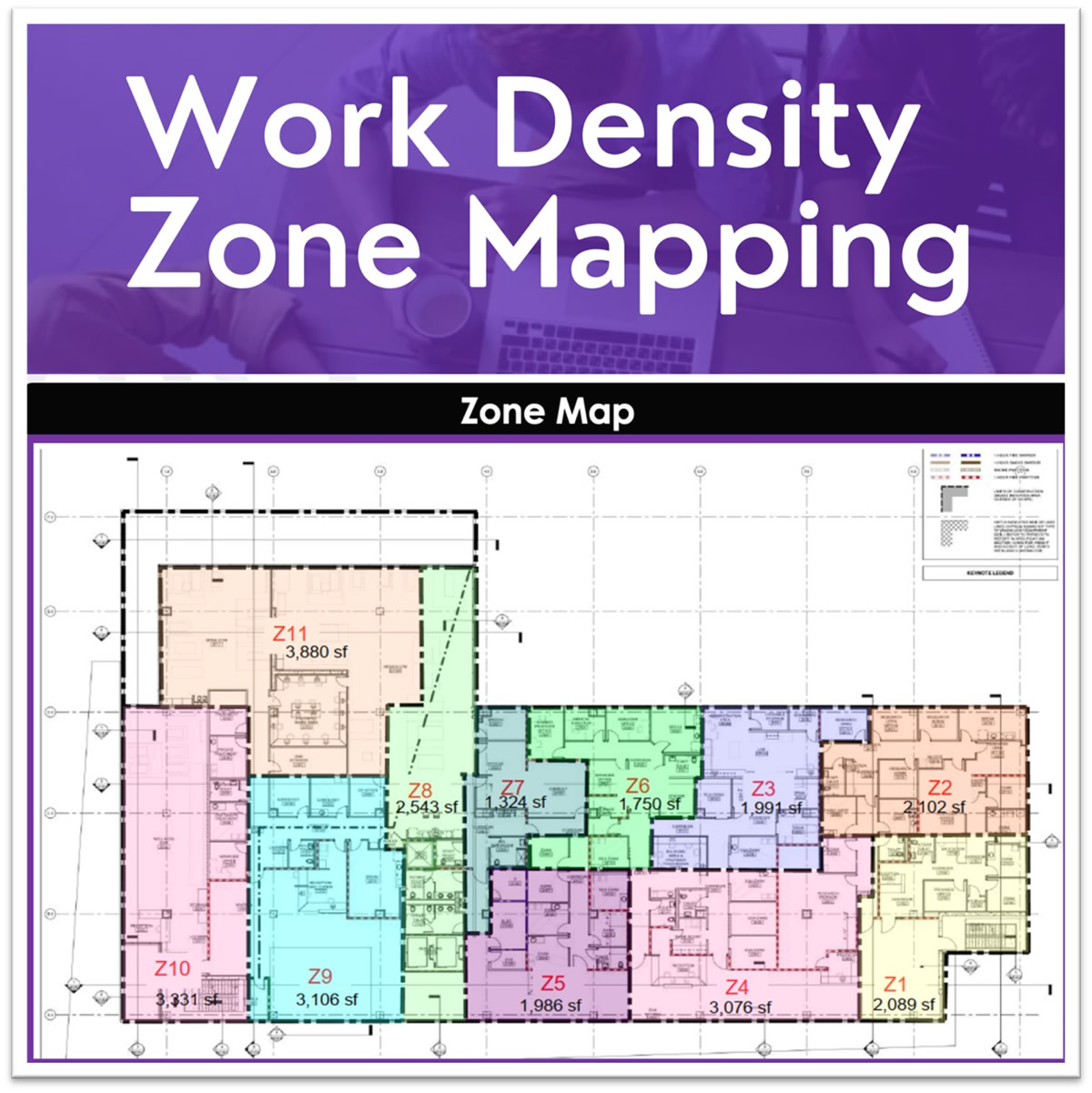

- Identify the right zoning for each phase.

- Pull plan the representative zone for each phase.

- Create the Takt phase from that single pull plan.

- Network all phases into an overall Takt plan.

- All Last Planner formats would be filtered within or from the Takt plan and commitments would be made within the framework of zones and Takt times.

I can show you what this looks like in an Excel format examplef:

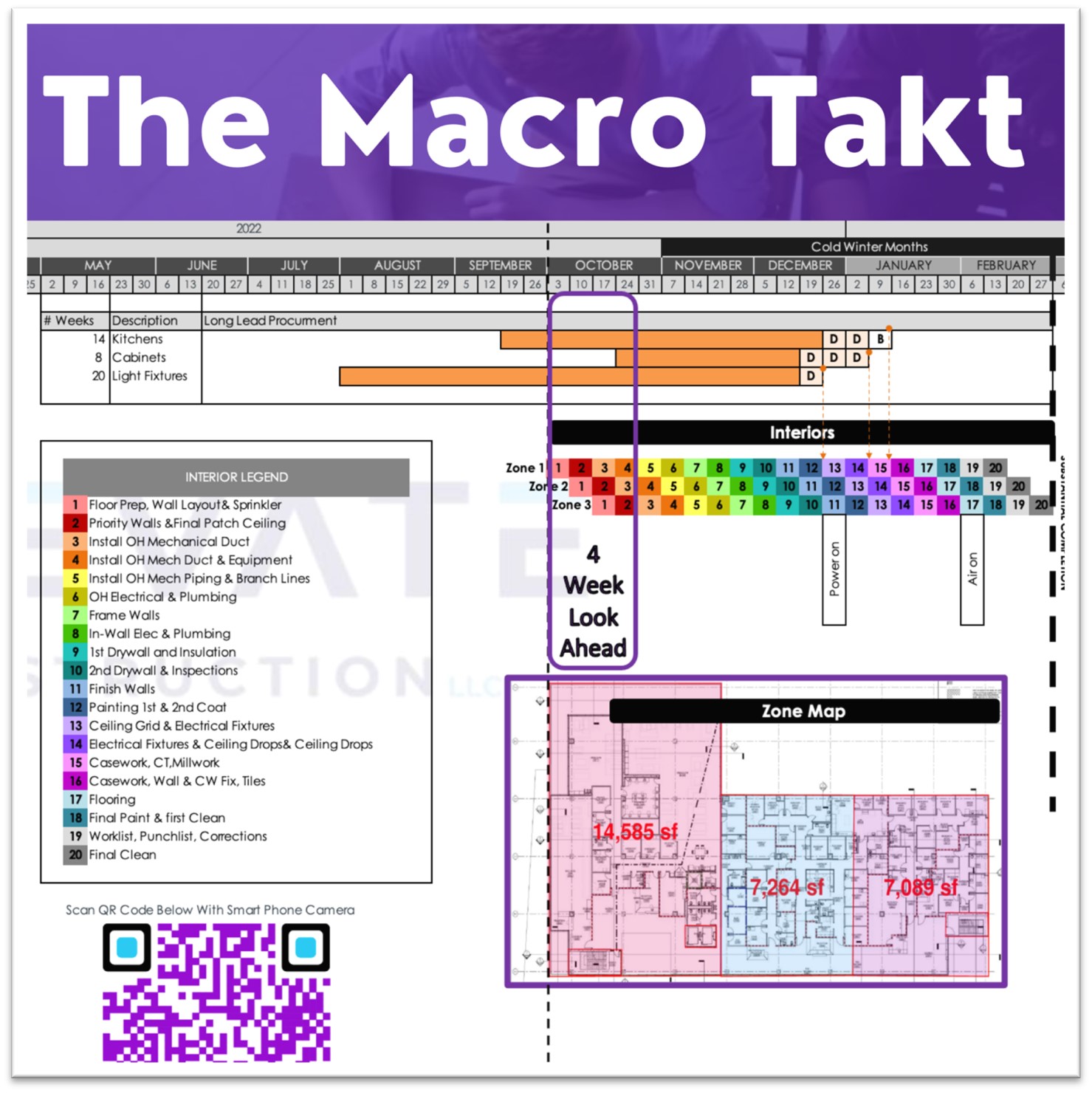

First, the macro-level Takt plan would be created in pre-construction:

Second, we would begin pull planning phases once trade partners are on board:

Third, we would make sure the zones and Takt time were optimized according to Little’s Law:

Fourth, we would analyze your zones to evaluate zone density and get your zones to be equal sizes:

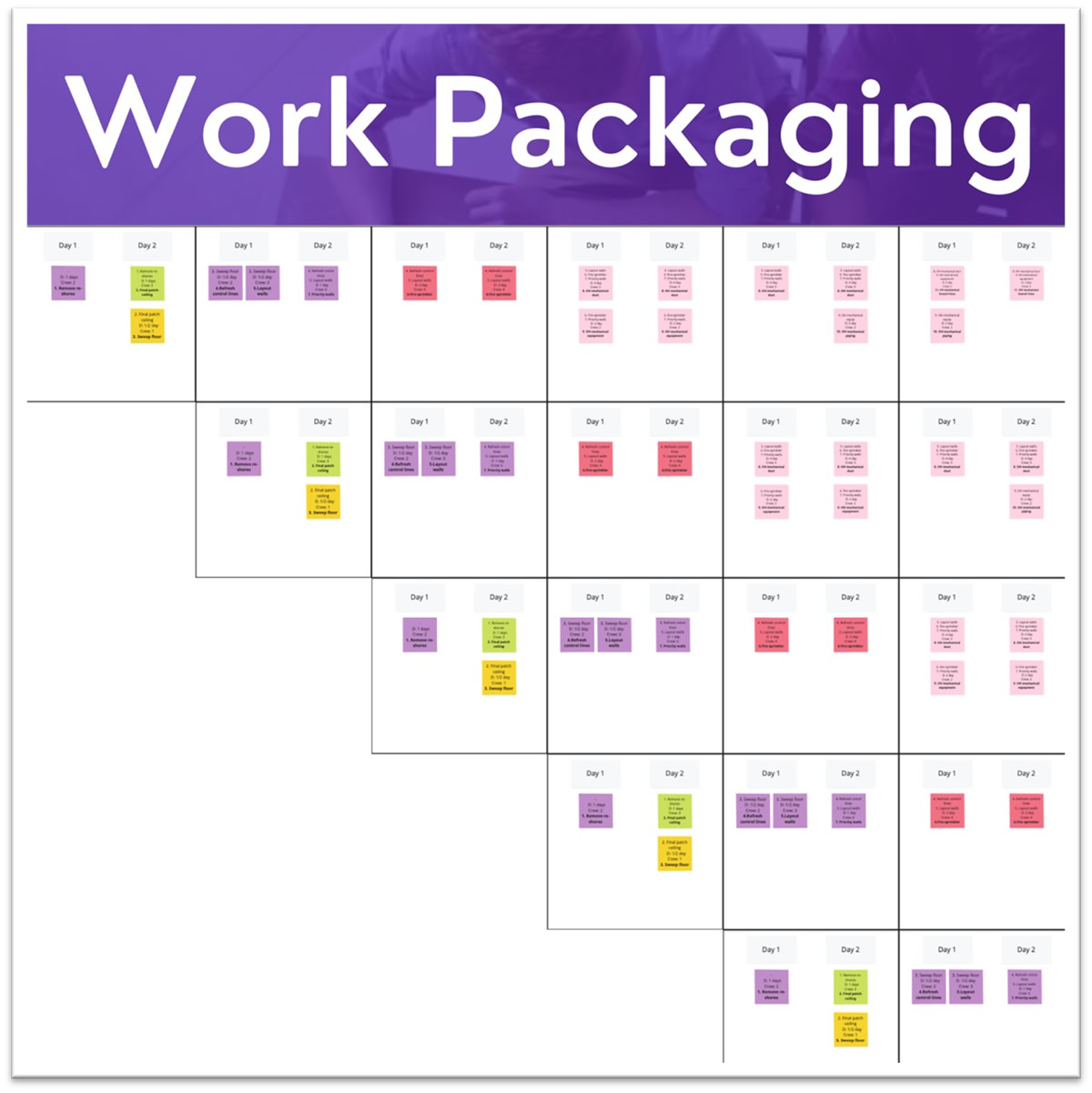

Fifth, we would package your pull plan into the right number of zones according to your new Takt time:

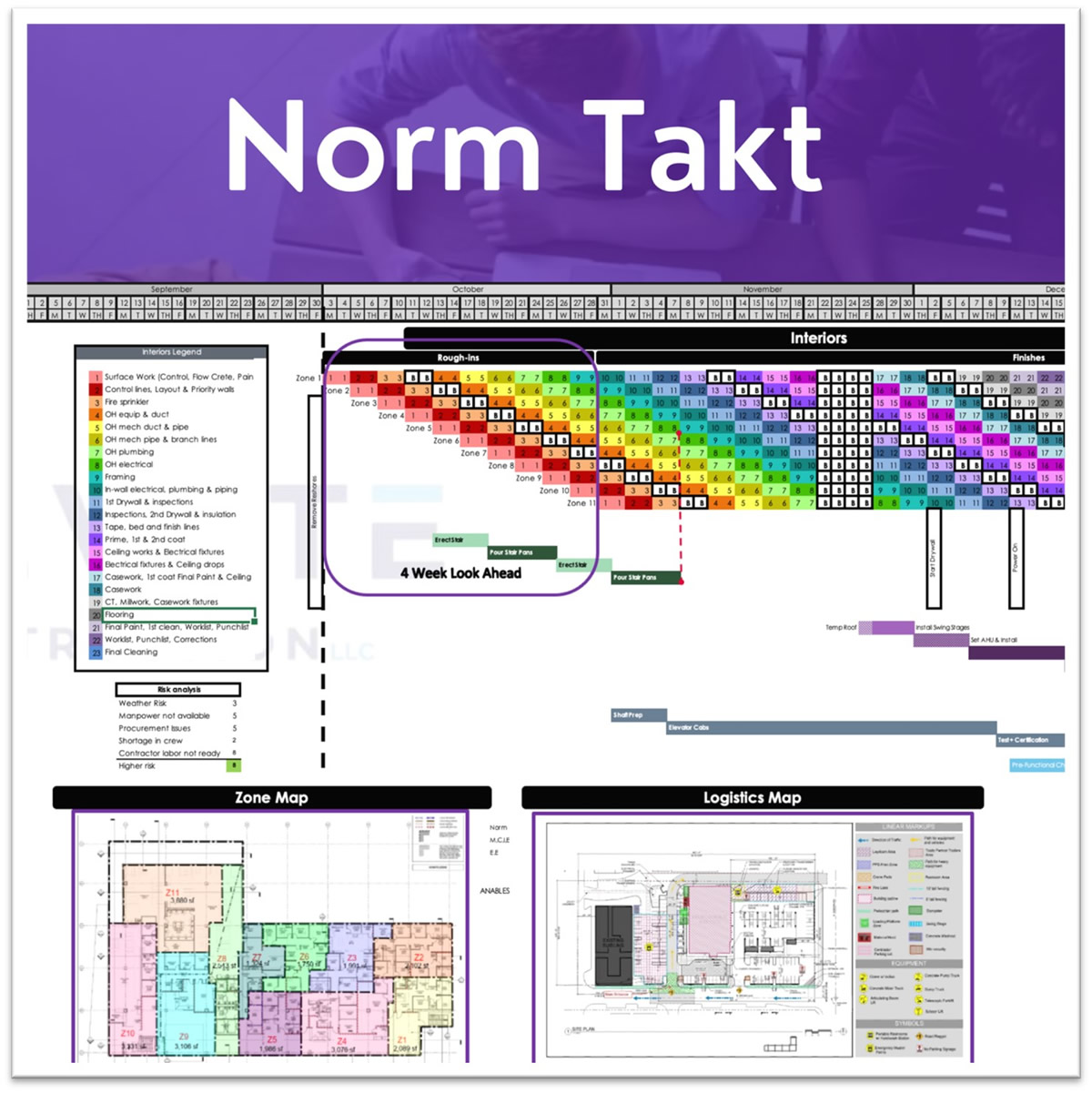

Sixth, we would create your norm-level Takt plan with buffers:

Seventh, from the norm-level Takt plan, look ahead and weekly work plans would be created:

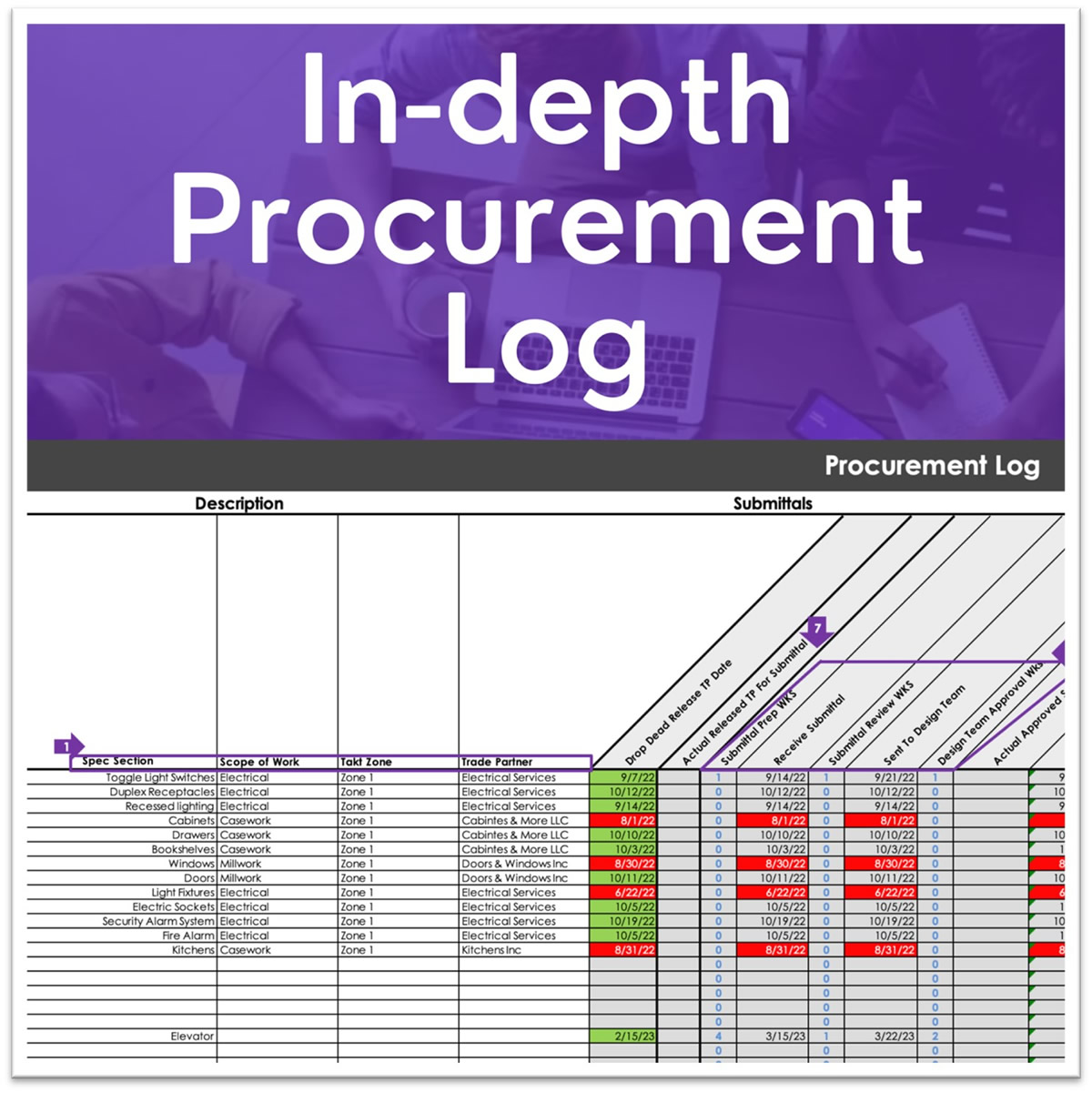

Eighth, we would then align our procurement log and schedule with the overall schedule:

So now, we have a plan that will resolve all 7 problems. Let’s look:

- Problem 1: Now that you have a schedule that respects trade flow and has buffers, you now have a schedule that has a correct duration with proper milestones.

- Problem 2: Now that you have optimized your Takt plan, you have the right number of zones, and your pull plans are just the right size. You have gained time and have a flowable schedule.

- Problem 3: Because your schedule is predictable and accurate, your procurement can align nicely with the schedule and items can show up on time if they are available.

- Problem 4: Because the plan is shown on one page and easy to update, your schedules stay vertically aligned and are always accurate.

- Problem 5: Because your norm-level Takt creates the basis for your weekly work plans, your foremen can now observe and adjust a plan that has flow and save hours every week.

- Problem 6: Because you have protected trade flow, the commitments your trades make can be met and your schedule is now realistic.

- Problem 7: Your plan now has repetitive areas, and you can get better at each area as you go, which means you will gain time. And your PPC will show you how to improve as you go because it is measuring real plays that will repeat.

Problem Solved!

All we had to do with the first Last Planner System was to get the right master schedule to pair with it. All we needed to do was pair Last Planner and Takt.

My Two Cents on the Value of Last Planner 2.0

We are currently not utilizing the full capabilities of Last Planner System 1.0 because we need the right master scheduling system.

Basically, everything currently wrong with LPS is that we base it on CPM the wrong way. So, everything wrong with LPS is CPM. The goal of Last Planner System 2.0 is to base it on doing Takt & Critical Path Method the right way.

Takt, Last Planner System, and Scrum are like the first time I saw the iPhone. When I first saw the iPhone I thought, “Wow, that is cool. I could use that, but it is not necessary.” It was a neat new thing.

Now, I realize what Apple did with the iPhone revolutionized communication and how the business and entertainment industries (and even us everyday citizens) share content. The iPhone interface literally changed the world. Even all the wonderful Android users out there would have to agree that the Android phone followed suit and copied many aspects of the user interface—even if they think Android is better, and even if it is better. The iPhone improved an entire industry.

One day people will wake up to a world where Takt is not just a nice thing they could use. They will realize it is THE way we schedule construction projects. Takt, Last Planner System, and Scrum are genius approaches. It’s time to implement them fully if we are going to change the construction industry for the better.

P.S. Sometimes I hear people say, “I have tried Takt, and it does not work.” Respectfully, that is incorrect. Most likely you have tried CPM in a Takt format, and it did not work. Takt is just as agile as Scrum, just as visual as LPS, and just as logical as our builder minds.

The issue is that people do Takt wrong when they:

- stick with only a 5-day Takt time.

- use the weekends as their Takt drum beat and lock themselves into weeks.

- do not split, combine, and level work packages within Takt wagons.

- do not include enough buffers in the phase to cover their risks.

- don’t create the plan early enough in pre-construction and therefore don’t have the right project duration target and consequently the right budget.

- don’t involve and align the builders (supers and foremen) in the plan development.

- don’t immediately begin managing material procurement on a log, or in the Takt plan at least, by the design development phase of design.

If you follow the rules when you create a Takt plan AND you pair it with Last Planner, you will be working in Last Planner 2.0 territory.

This will become the new norm. Let’s learn it together.

On we go!

Be sure and follow Jason Schroeder on LinkedIn!