The Bungee Effect is named after bungee jumping, which is an activity that involves a person jumping from a great height while connected to a large elastic cord. The launching pad is usually erected on a tall structure such as a building or crane, a bridge across a deep ravine, or on a natural geographic feature such as a cliff. The thrill comes from the free-falling and the rebound. When the person jumps, the cord stretches, and the jumper flies upwards again as the cord recoils and continues to oscillate up and down until all the kinetic energy is dissipated.

The bungee effect as described in this blog post is an effect where a trade crew recoils and pushes late when the general contractor or owner attempts to burden the trade partner by having them work in too many areas at one time.

One of the biggest unknown facts in construction is that dissolving logic and burdening crews, even if it was moral and ethical (which it isn’t), is just not physically possible. This is what most leaders don’t see. They don’t see the effect of burdening trades and getting out of flow.

So, let’s dive right in here.

The Bungee Effect

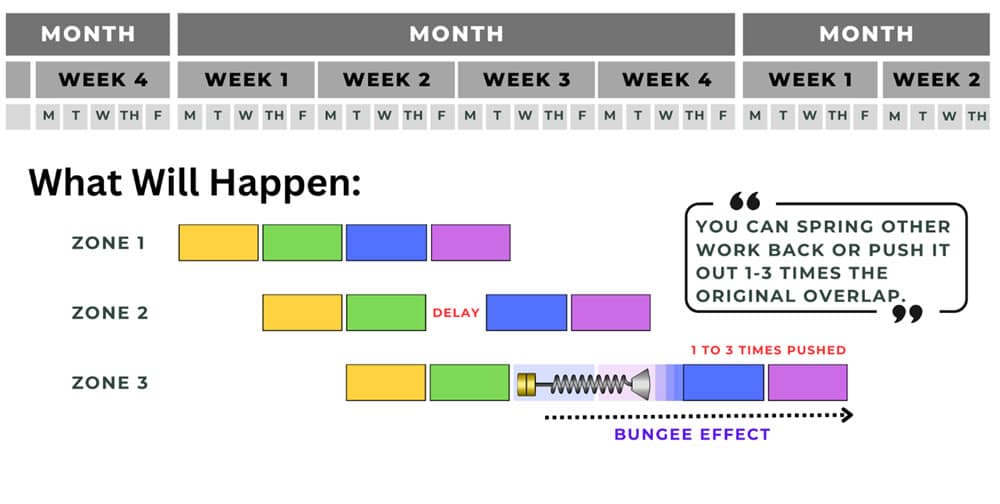

Note: all the following formats will be in a time-by-location format, so you can see the effect.

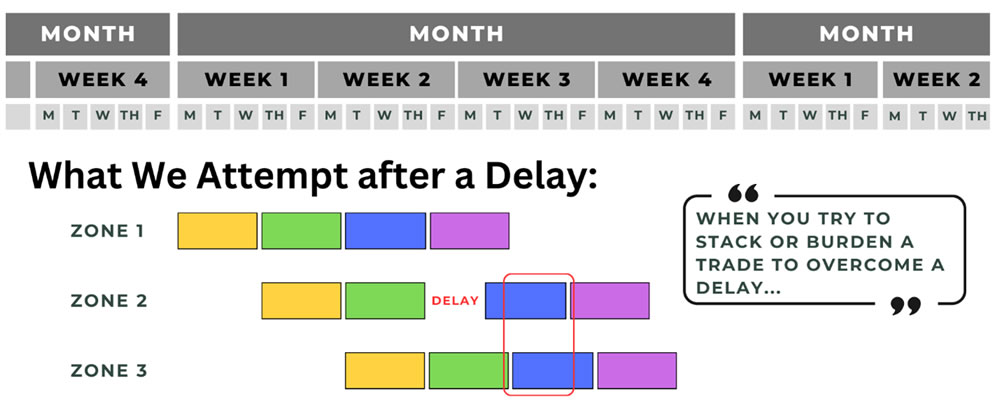

In the picture below you see the blue wagon in Zone 2 has experienced a delay. Most construction managers would default to just asking the trade partner to do the work in Zones 2 & 3 at the same time and just help the project recover at their expense. What they don’t realize is that this is impossible.

What really happens when construction managers and trades attempt this approach is called “the bungee effect.” The zone-stacked activity or additional work will either stay where it was or will push out within a range of 1 to 3 times.

What really happens when construction managers and trades attempt this approach is called “the bungee effect.” The zone-stacked activity or additional work will either stay where it was or will push out within a range of 1 to 3 times.

Why you ask?

Fair question.

The answer is because you will enter the productivity spiral. This spiral is composed of productivity losses that will happen to you when you overburden people and crews.

Let me take you through it.

Once you burden the trade…

- They must either work more with existing resources or bring in more resources.

- If the trade brings in more resources, they will now be batching work throughout the project which will lead to context switching and a loss of productivity.

- With more people on-site, or in the crew, the team size increases, and communication gets more complex, with more communication channels to be managed.

- With more people in crews the composition of the crews changes and foremen assignments change. Workers are then separated from their normal environment. Without a consistent leader, culture, language, and working habits, the crew loses productivity.

- With new people coming to crews, they need to be onboarded. Onboarding to 100% productivity takes at least 7 days at best. Meaning the newer people are not fully up to speed and productive out of the gate.

- Until new resources reach additional productivity, crews typically begin working overtime which fatigues and overburdens the crew. This only helps production for a few weeks until it plummets.

- Once overtime begins and new people enter the scene, the team takes their focus off quality. They then get distracted.

- Once distracted they begin installing work wrong and are riddled with rework which costs 2 to 12 times the original cost and time duration.

- With all the rework happening the project team loses focus from planning, preventing, and removing roadblocks out ahead and they begin to experience stops and restarts.

- At this point the project descends into chaos, much like a dumpster fire inside a burning building, inside a nuclear bomb, during a solar flare.

These items are what recoil the desired acceleration and delay your project. You just can’t overburden people without consequences.

Still not convinced?

Well, let me show you another set of graphics to illustrate the point.

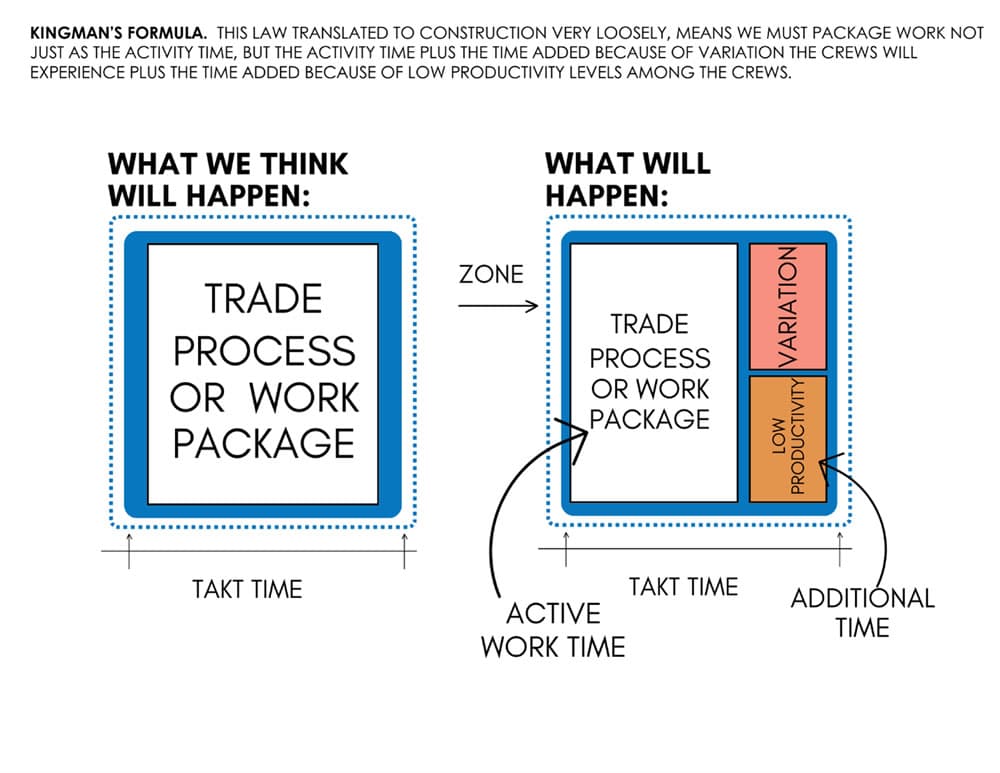

One of the Lean principles we must use from manufacturing and adapt to construction is called Kingman’s Formula. Roughly translated it means that an activity duration is not just how much time the work will take for that activity, you must also include in your duration the time spent adapting to variation and lost from low productivity.

Now, I hope you are sitting down when you see the next part.

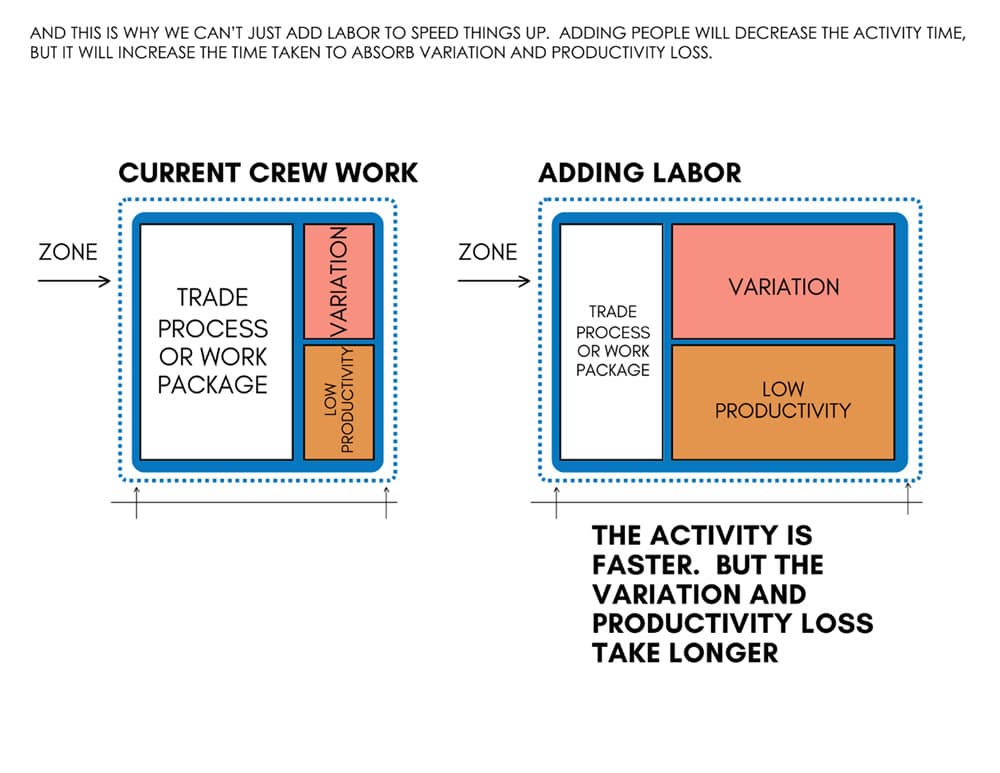

When you have an activity that is in normal flow, you have an average amount of additional time for variation and production loss. Meaning there is an average amount of non-value-added steps that take time in the overall duration. When you overburden the crew and add more people to the crew, the activity duration will decrease, BUT YOUR TIME ADDED FOR VARIATION AND PRODUCTION LOSS INCREASES.

So, you do not gain anything. In fact, in most cases, it takes longer.

This is the invisible reality of construction. To go fast you must stay in flow and on a rhythm.

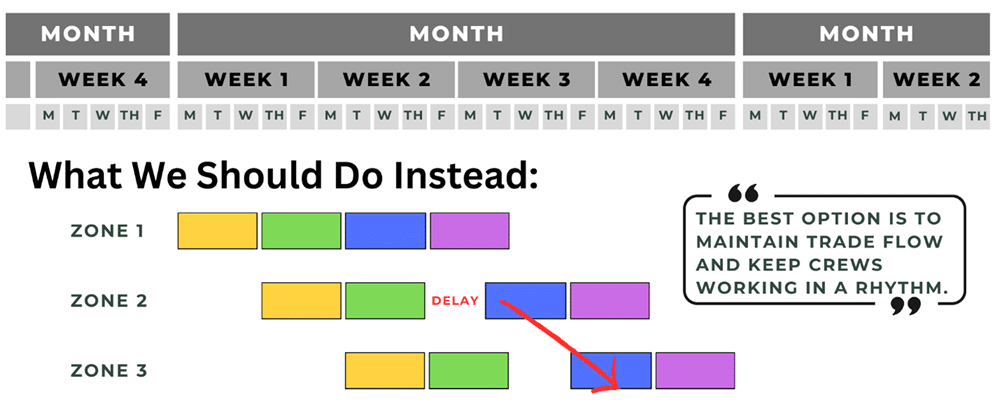

So, what should we do when we have a delay?

When we have a delay, we need to cascade that delay and stay in flow. This prevents the trade from getting hurt and the project from spiraling out of control.

And you may ask how that is even possible.

And you may ask how that is even possible.

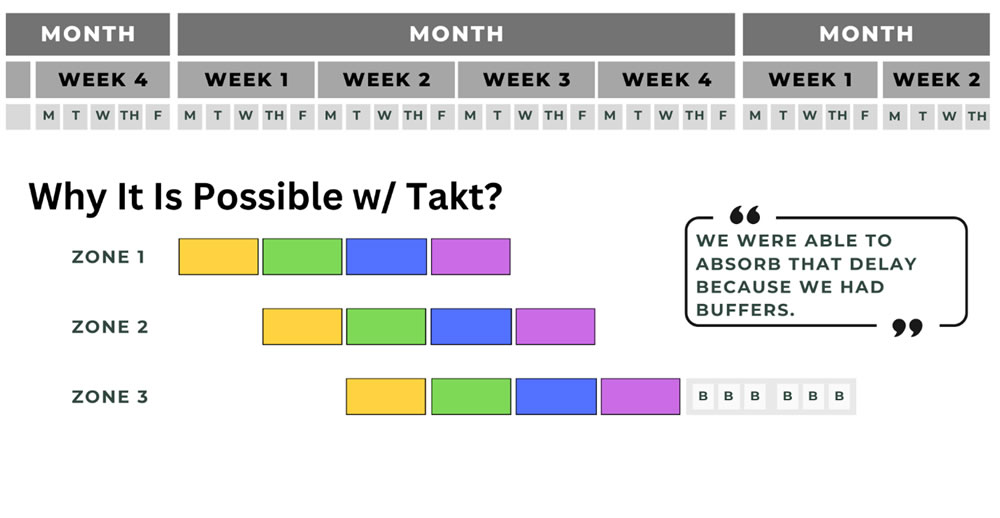

Well, please remember that with the Takt Production System®, we can gain buffers through various zoning strategies. Most delays can be recovered and absorbed this way.

Delays happen. You have two choices when they do: 1) you can rush, push, panic, and stack to your detriment, or 2) you can maintain flow in the proper system.

Delays happen. You have two choices when they do: 1) you can rush, push, panic, and stack to your detriment, or 2) you can maintain flow in the proper system.

Remember the bungee effect: more resources do NOT EQUAL shorter durations, but flow always will.