Lean expert Jason Schroeder of Elevate Construction explains & illustrates the use of a Takt time formula matrix & how to optimize sequences and buffers. Read on to learn to take Takt to the next level!

Taking Takt to the Next Level

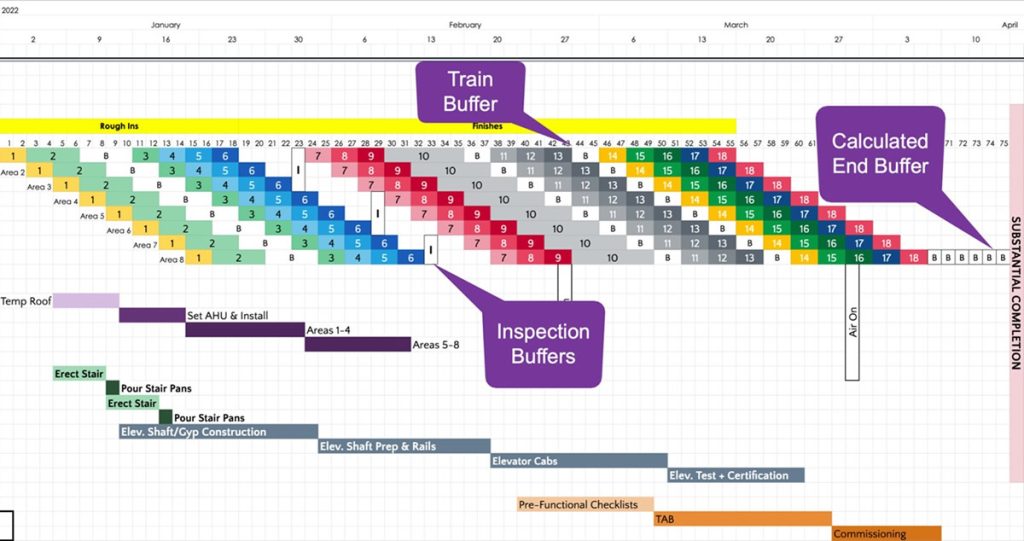

Welcome back everyone! In my last blog post, I covered how to create a Takt plan from a pull plan and left you with a question: “So, how do we take this coordinated plan to the finish line and make it look like the plan below?”

The answer is, we must first optimize the sequence and add buffers.

So, here we go…

Scheduling with Takt and the Last Planner® System (LPS) allows you to take a project with a linear schedule and implement strategic overlapping. This leads to shorter project durations and buffer time, but how is this possible?

In this blog post we would like to dive deeper into Little’s “Takt” Law, also called “Dlouhy & Binninger’s Law.” This law describes the relationship between inputs in a Takt plan. It goes something like this:

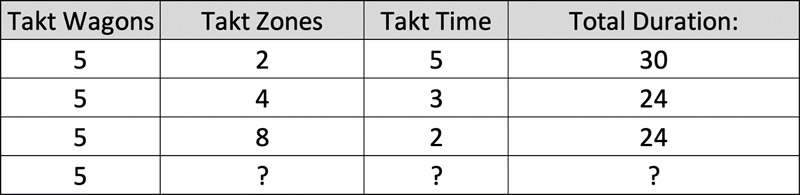

(Takt Wagons + Takt Zones – 1) x Takt Time = Total Duration

(TW + TZ – 1) x TT = TD

Let’s dive into the math and really understand how this works. To do that we need to turn to one of our best friends, Excel.

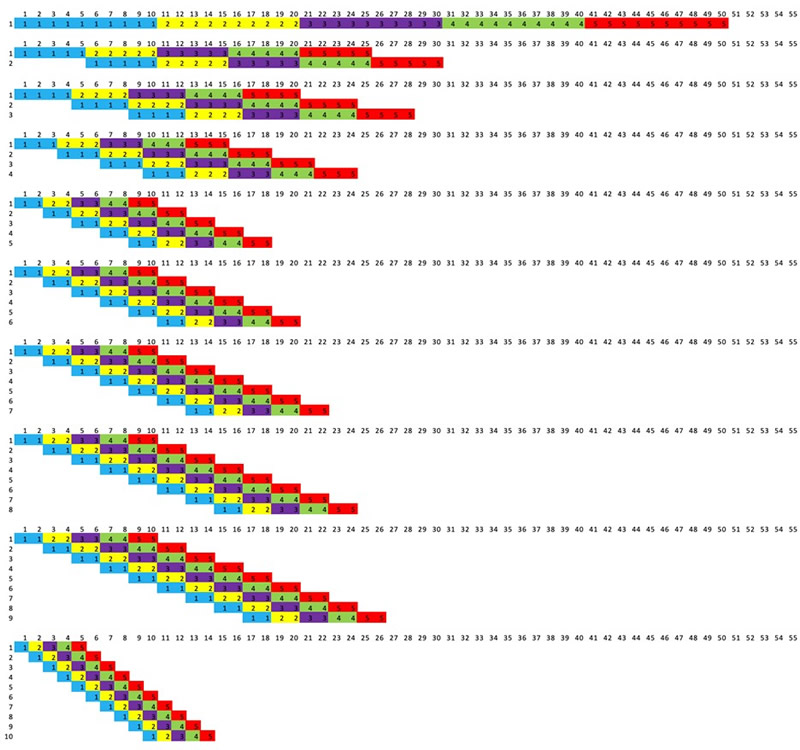

If you start by building a simple matrix that shows a few of the possible Takt plans for a given set of inputs and the actual Takt flow diagram for each one. Let’s use the same example we have shown up to this point and start with a single floor in a medical office building with 26,000SF. For simplicity, we will simulate just the rough-in phase with five Takt wagons. This is what it looks like:

Takt Time Formula Matrix:

Visual Simulation:

This is the same matrix that Spencer Easton uses in his video describing this same concept. It’s a great video and you should definitely check it out:

Little’s “TAKT” Law in Construction – Video:

Once the matrix is built, we may find we have more questions than when we started.

Questions like:

- What is the “best” Takt plan for this set of inputs?

- Why does each trade get 2 extra days when going from 2 sequences to 4 sequences? And why do they get 6 extra days when going to 8 sequences?

- What about other numbers of sequences?

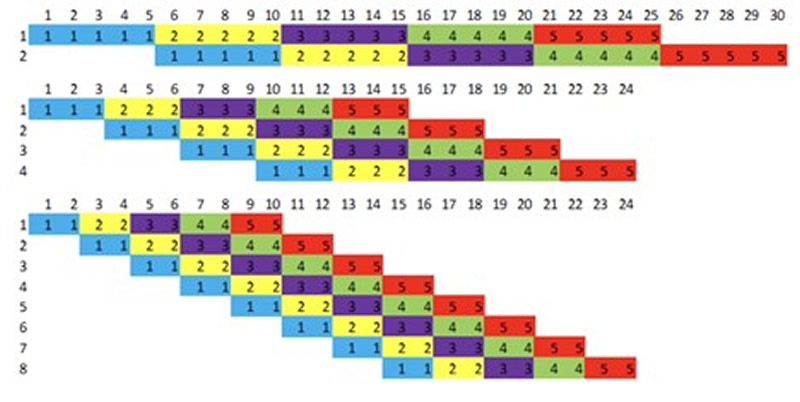

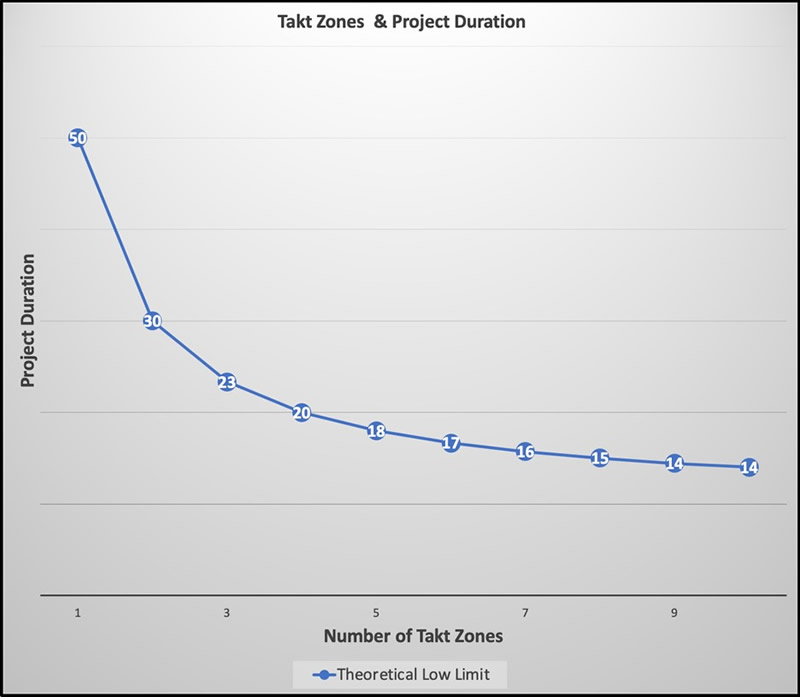

To answer these questions, let’s turn back to our friend Excel and graph out what the theoretical lower limit for this set of inputs ranging from 1 and 10 sequences. This will map out, based on the formula, the fastest we could build this phase of work based on reducing Takt Zone sizes.

Theoretical Low Limit Simulation:

Graph of Project Durations:

This looks pretty cool, right? But we likely would not work 3.33 or 1.667 days for a scope of work.

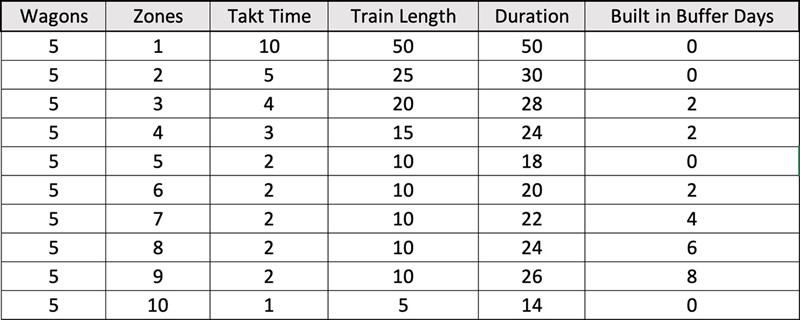

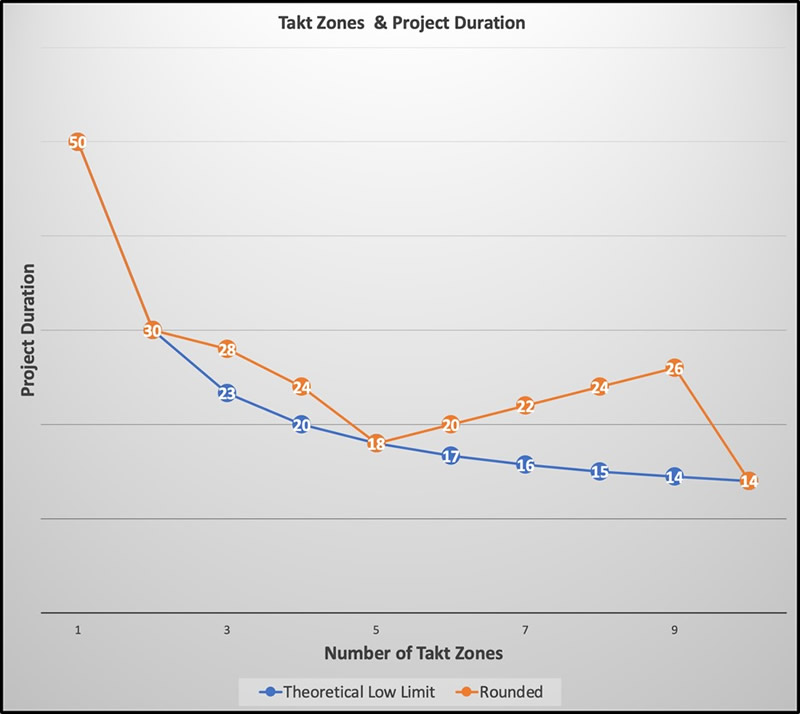

So, lets update our table to have rounded days of work:

Rounded Table with Whole Days:

Project Duration Based on Rounding:

Simulating all 10 Options:

Crazy stuff right! Rounding changes everything! You can see how important it is to know some of this information up front during the planning phases of your project. Understanding how it affects duration is critically important to formulate the best Takt plan. Notice that the theoretical lower limit intersects with certain numbers of sequences or zones. These Takt plans will be lean and mean, but not always possible, or desired. Sometimes a certain number of sequences or zones is better for a particular project, but it is important to know how this affects the Takt plan relative to possibilities. This way a more informed decision can be made to balance all the factors involved in completing large scale projects.

Rounding is also where the extra 2 days and 6 days of trade work come from. Rounding each Takt time up accrues over the project. This gives each trade more time on the project and still reduces the overall project duration.

It becomes obvious that the utility of a tool that would model all the different possible Takt plans for any given set of inputs would really help. This is the magic of Takt planning. By taking our pull plan sequences into a Takt phase we can optimize the sequence and gain time.

Construction Interruptions & Delays

Lastly, what do we do with that time we gained? Glad you asked!!! We create buffers in the system. No master schedule should be planned without buffers in it. Construction will always have interruptions. Construction will always have delays. So, we need a way to absorb those delays. And we do that with buffers!

Let’s return to the original question: “So, how do we take this coordinated plan to the finish line and make it look like the plan below?”

The answer is:

- We optimize the sequence and gain time.

- We use the gained time to add buffers.

- We use the buffers to absorb interruptions in the schedule.

When you see a pull plan, you are seeing a single sequence. That is great! The next question is, “do all the sequences by area flow together in an optimized network of sequences?” The Takt format does this for you. Stay with us as we discuss next week how a Takt plan can help you create a 6-week Make-ready Look-ahead and Weekly Work Plan.

On we go!