Persistent problem solving using Lean solutions in the construction industry. Field Driven Lean’s Brian Winningham explains how to solve those pesky persistent problems with an array of Lean tools.

No Rats Allowed!

I once worked with a superintendent named Red who used to sign off our telephone calls with an odd phrase: “All right, I’m gonna let you get back to your rat killing.” It’s a weird thing to say, but I’ve always thought it was on the money as a description for the work that we project managers do, and for our industry as a whole. The AEC industry has a “rat killing” problem.

That’s meant as a metaphor, but it works literally as well. I’ve worked on quite few projects over my twenty years spent a project manager. Most of those involved working from a trailer or modular building on the project site. On a small handful of those projects, my teams experienced a rodent infestation in our workspace. In my experience, they usually approached it the same way: denial. If the interlopers have chosen a place in the office you can avoid, you can ignore the little black pepper specks that have suddenly started to appear. If it is your desk, your table, or the kitchen, it is a little harder to ignore, but not impossible. A quick bleach wipe down first thing in the morning and you can forget about it until tomorrow. Problem solved—but problem NOT staying solved.

There are a couple of problems with ignoring rodents though. They are prolific breeders and when they find something good, they invite all their friends. At some point, they become impossible to ignore and a lot more trouble to deal with. First you must identify and close-off all their points of entry. Then, they must be trapped and removed one by one. It isn’t easy to get rid of them (and, frankly, it’s pretty gross). I’m certain it wasn’t a task anyone ever anticipated when beginning their construction career. By far, the best solution I’ve seen is to fill all the holes in your office trailer where animals could gain access (like the ones you drilled through your floor to install internet) with steel wool. Mice can’t chew through it like they can foam or insulation. If you think ahead and fill these holes as you make them, then you never get a rodent problem in the first place.

Ignoring the Problem

I’ve seen some project teams address their project problems the same way some of my teams dealt with rodent infestations. They start by ignoring their problems, hoping they will somehow magically disappear. One way we do this is by blaming it on something out of our control, like the owner or our trade partners or any “outside force”. We end up trying to shift blame the same way we try and shift risk. For instance, many folks blame the current supply chain issues on Covid. While the pandemic has made our supply chain problems easier to see and much more extreme, these problems persisted well before 2020. The same logic applies to other problems we chronically ignore in this industry, like suicide, mental health issues, diversity equity and inclusion (DEI), workforce development, technology, employee retention, aging workforce, prompt payment, and more.

Because facing problems head on and dealing with them is scary, people tend to avoid or delay dealing with them. That NEVER leads to a good result. The projects where someone jumped in and began working the problem as soon as those black specks started to appear usually meant we were over the infestation in the matter of a few days as opposed to weeks or even months for those that stayed in denial.

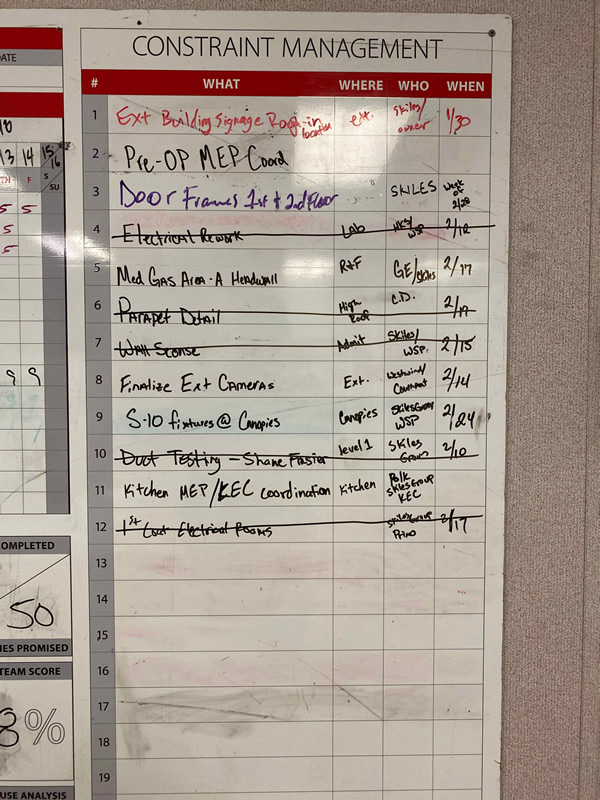

Constraint Management Board

A great countermeasure to procrastination—and a way to visually surface problems on your project and to work them systematically—is to keep a project constraint board. You must make this board/log a featured part of every meeting you hold: one project, one constraint log (YMMV). Keyan Zandy of The Lean Builder wrote an outstanding article about how to get started and manage a constraint board on your project. You can find that article here: Constraint Management Techniques on the Jobsite.

Scrum

Scrum is another great tool for making work visible and easy! Visit scruminc.com to learn more about how Scrum and Agile systems can help our issues bubble to the top before they become a serious problem.

What about those folks doing that daily bleach wipe down and kicking the can down the road until tomorrow, EVERY DAY?! They are issuing that CPM schedule revision every week but ignoring the real problems and not offering any real solutions on how to overcome the issues. These folks tend to fall back on the contract to force people to comply, not understanding how little the contract actually buys. When you start quoting the contract in emails and letters to subcontractors, what that “buys” you are really terrible working conditions, delay claims, extremely long punch lists, poor quality, and higher prices from the trades on your next projects, if they will even give you a price on the next one at all.

An alternative to approaching your problems like we detail above is to buy these same trade partners lunch. Sit and eat together and talk about anything but your current problem(s) until everyone finishes eating. After lunch, as the leader you will need to stand up, look those folks in the eye, explain the situation as best you know it, and humbly ask for their help. If they have some arguing that they want to do, then just stand there and listen to them. When they finish, tell them you hear them and ask them again if they will help. At this point, they will usually either agree to help or become so frustrated with you that they will leave and subtract themselves from the problem. This approach has helped me on several occasions and has always turned out better than sharing my knowledge of the contract with those folks in some sort of correspondence.

How can we apply steel wool to our problems, to head them off before they can derail us? Steel wool works like culture. The type of culture on your project is a great indicator of your project’s success. What kind of reputation do you have? How do the people you work with see you? Do you seek input? Are you humble? Brash? Funny? If you constantly have to yell, if the subcontractors aren’t following your plans, if you are constantly frustrated, or if your schedule is changing every week, then your culture is the best place to start to get things on track. All of the ways that we show up impacts how culture gets built into your projects. We all play our part in creating the culture we have.

Persistent Problem Solving in the Daily Huddle

Daily huddles are a great place to start building a better project culture. This is also the perfect place to practice active listening as the leader, to make sure everyone understands the plan. Another tactic you can try is to have someone else lead the meeting every so often. This allows you to step outside the huddle, so you can see and hear it as an observer. This can help you see areas for improvement for your huddles regarding inclusion and participation.

There are lots of great posts and videos and other media out there detailing the steps to getting started with daily huddles. Some key things to remember as you begin your journey are to keep the daily huddle short (10-15 mins) and focused on production. Also, stay curious, be humble, and strive to be an active listener. If you can do those things consistently, your project will improve over time, even if it is already very good.

Be on the look-out for the little black pepper specks, because it is the little problems ignored over time that cause us the greatest issues on our projects and in our lives. Being proactive about addressing these problems is a great first step to overcoming your issues. I hope some of the tools I have talked about today can help you complete those next steps in your construction journey. Please respond in the comments with your best “rat prevention” techniques and stories. Thank you for reading, I hope everything in your life gets better, and easier.

https://rangerwinnie.medium.com/