Scorekeeping in The Last Planner System in Construction

A few years back, I was walking a project with one of our superintendents who was concerned about a few trades falling behind. As I reviewed the Gantt schedule and compared it to what I saw, I agreed that it looked like we were behind. I approached a plumber, who just finishing brazing a med gas line, and asked if he could tell me the date he was working towards to hit his in-wall inspection. He shook his head and said he didn’t know. When his foreman came over, I asked if he knew the milestone for the plumbing in-wall inspection; he told me he couldn’t remember. When I asked if he knew the exact date that the project was due, he admitted that he didn’t.

“We are pushing hard,” he promised. “We’ll get there.”

I started to quiz others. I asked the mechanical foreman and the electrical foreman what date they were working towards for overhead inspection. Neither could recall.

“I’ll have to check the schedule,” they said. “We will get there.”

I was surprised. I asked my superintendent if we were issuing a six-week look-ahead every week. He affirmed that he was and pointed to the stapled multi-page Gantt schedule that was in my hand, saying, “This goes out every Friday.”

Over the next few months, whenever I walked a project, I would ask the trades if they knew their milestone or completion dates, and I found that most did not. As much as we talk about scheduling and spend effort pull planning and creating weekly work plans, the fact is most foremen (and especially their craftspeople) do not know milestones or completion dates. They are just working as hard as they can.

I shared my frustration with a mentor of mine, and he suggested I read the book The 4 Disciplines of Execution by Chris McChesney. I burned through it and was fascinated with the third discipline, which discusses the importance of keeping a compelling scoreboard.

According to the authors, to execute at the highest level, you must make sure everyone always knows the score so they can tell whether they are winning. People and teams play differently when the score is being kept, and the right kind of scoreboards motivate players to win. This concept was a gamechanger for me. I kept asking myself: how can we keep score in our industry? How can we be more transparent with the field? How can we create a scoreboard that compels action, and keeps energy and intensity directed towards the key milestones of the project?

The Last Planner System in Construction

Luckily for us, the Last Planner System™ covers many of these metrics—but it’s up to us to make them visual. Here are my thoughts and ideas around how to keep field teams focused on the score.

Keep it simple.

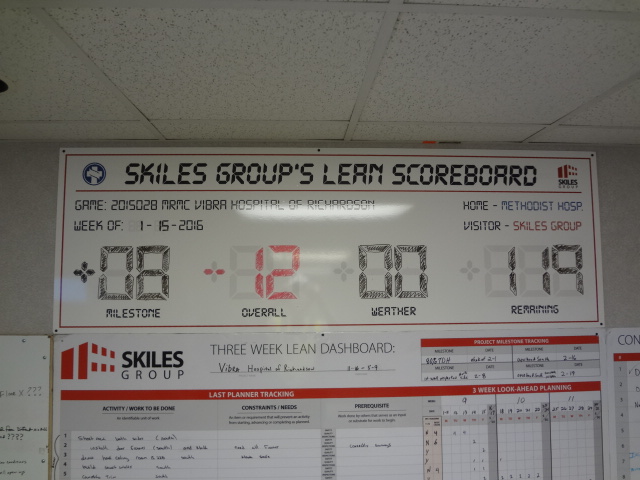

Our main scoreboard has only four metrics on it:

- Days ahead/behind the current milestone,

- Days ahead/behind on the overall schedule,

- Weather days, and

- Days remaining in the project.

(Yes, we share the real number of days remaining in the project with our trade partners. We are a team, and we should all be dialed in to the amount of time left in the project. Every day counts, and we should all know what’s left on the timeclock.)

Make it easy to tell if you’re winning or losing.

Use colors, charts, infographics, etc., to make sure the field can easily understand the score and the metrics being tracked. The Last Planner System’s™ Three-Week Look-Ahead and Percent Plan Complete tools are great places to start. Our three-week look-ahead boards display upcoming milestones dates for the field teams to reference.

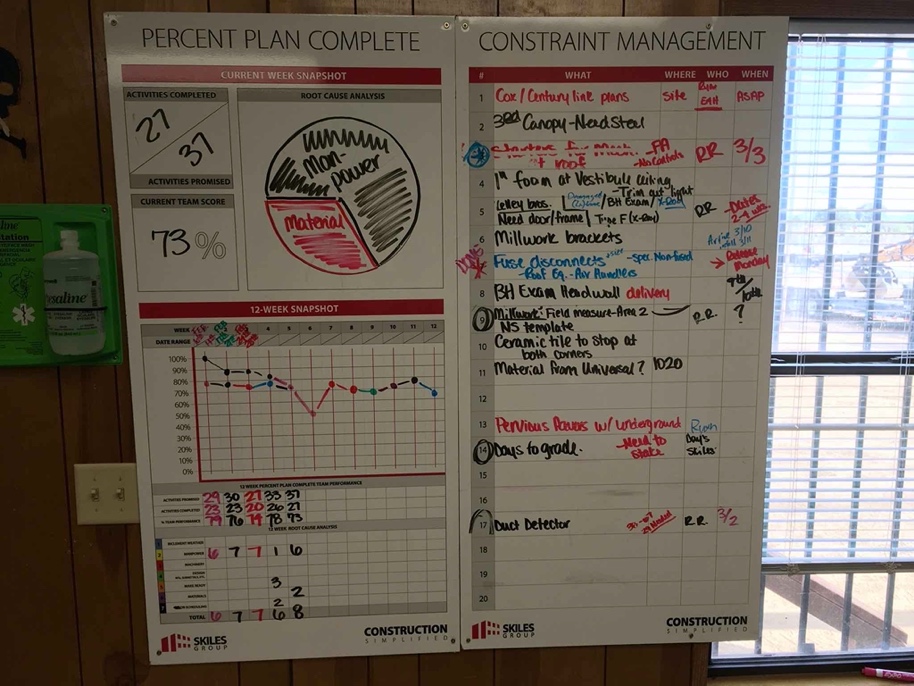

The Last Planner System in Construction – Percent Plan Complete Boards

Our Percent Plan Complete boards track the score of how well the team is keeping their commitments to one another. The Percent Plan Complete board can be printed on plotter paper or drawn onto a whiteboard; either way, it should be displayed where you will be having your daily huddles. You can build your Percent Plan Complete board with the following categories:

- Activities Completed

- Activities Promised

- Weekly Team Percentage

- Root Cause Categories

- Root Causes for Work Missed

- Twelve-Week Snapshot

After your final huddle of the week, tally up the number of activities completed and divide by the number of the activities promised. This will yield a percentage of commitments met.

You can also track root causes for work that was not completed. Predetermined root causes for missed commitments are:

- Weather,

- Manpower,

- Machinery,

- Design,

- Make-ready,

- Materials,

- Poor scheduling, and

- Other

As part of your root cause analysis, a root cause pie chart can be a great way visually understand what categories the root causes are coming from. And by dividing the number of root cause types by the number of missed commitments, you will have the root cause percentage by type. This helps to identify trends on the project, such as manpower shortages, slow design response times, and weather impacts.

It’s important that your scoreboards are in a place where the trade partners can see them. Upcoming milestones, days left in the project, commitments made/missed are all displayed as part of our Lean dashboard system, which is accessible to everyone. Sharing goals, progress, success, and failures with the team increases the odds that accountability will set in and performance will improve. Post this information up around the jobsite. Turn up the heat and see the results that you achieve.

Update it every week.

Update your visual metrics weekly. Your teams need accurate information, and it will allow foremen to have conversations with their tradespeople about weekly results, improved performance, and constraints that may be in the way of an upcoming milestone. By closely watching the handful of scores that really matter, the field can be more flexible and change strategy if needed.

Great field teams know—every day—if they are currently successful and what is required to win the game. It’s important that we share metrics that explain where the field is versus where they should be, because this information allows field leaders to solve real problems and make informed decisions.

By: Keyan Zandy, COO

Skiles Group

For more from Keyan, see The Lean Builder – A Builder’s Guide to Applying Lean Tools in the Field or Connect with Keyan on LinkedIn.