Building material delivery scheduling and tracking is an essential element of a Lean construction jobsite. Lean expert and author, Keyan Zandy explains.

Uncontrolled Material Delivery

It was early on a Friday evening when a flatbed 18-wheeler, loaded up with pallets of brick, pulled up to my jobsite gates. This was early in my career, and I was tasked with locking up the jobsite for the weekend. I was surprised to see a delivery this late on a Friday since the mason had rolled out an hour earlier and I knew no one would be there to receive and unload this large delivery of masonry.

Agitated, I spent the next few hours slowly operating equipment to unload the pallets, knowing I’d be back Saturday to help the mason move it again to where it actually belonged (it was a big project, multiple buildings with different phases, and brick needed to be staged in several locations).

Feeling very victimized, I called my superintendent to complain—about my Friday evening, and my Saturday morning, and all of the brick I had to move (twice!). The phone was silent. Then, finally, this: “Sorry bud, get used to it! This is just how our business is. This happens on every project.”

Just-In-Time Deliveries

I’ve never been very good at taking “This is just the way things are” for an answer. I was early in my Lean journey then and had recently read about “just-in-time deliveries.” So, I decided to make my very first materials delivery board (which was nothing more than a whiteboard with a title and the days of the week written on it) and told the trades: if you have a big truck delivery, it’s gotta be on this board or we’re not going to accept it.

When we sent our first delivery of structural steel away, the field knew we were serious. It’s not that we were trying to be hard asses; it was because we began to notice how much waste we were experiencing onsite by not monitoring what was coming onsite and when. It really helped ensure that we were not taking on too much material at one time.

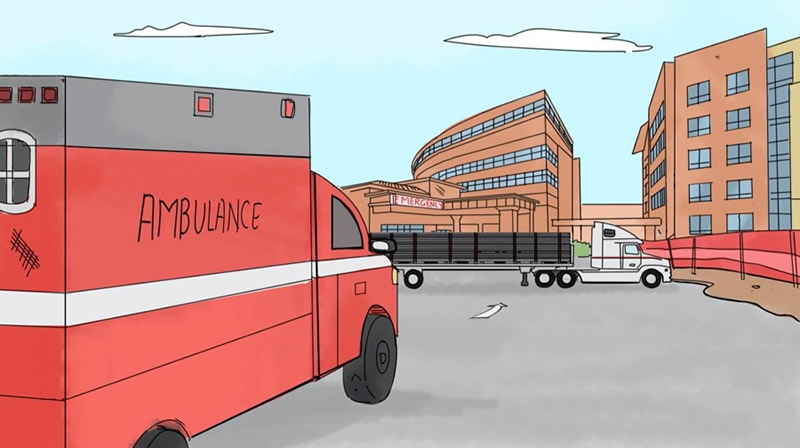

I noticed the improvement almost immediately and was excited to take this success to my next project on an occupied healthcare campus where monitoring deliveries would be even more important than on a greenfield site.

Continuous Process Improvement

Everything was working perfectly—until the day I got an angry call from the president of the hospital. There was a flatbed truck full of sheetrock blocking the entrance to his ER, and an ambulance was trying to get through. You can imagine how frantic I was as I ran down there. We got the truck moved, and then I got with the drywall foreman and asked him, what the #$@&! And his response was, “Hey man, it was on the delivery board!”

It was at that moment that I realized that the board had a lot of room for improvement. We were only tracking what was being delivered and what day it was being delivered. Going back to the board, we added these additional columns and rows to answer the following questions:

Material Delivery Questions

- Who has the delivery?

- What is being delivered?

- When is the delivery scheduled (day and time)?

- What type of truck is it coming in?

- Where is it going to be unloaded?

- How is it going to be unloaded?

Making these improvements was truly a game-changer. Our trade partners were doing a great job of making sure that they weren’t bringing materials onsite until they were needed and we eliminated a lot of the eight wastes that occur specifically around materials, such as moving things twice or having too much inventory. This material delivery board is now a standard for all our projects.

If you’re not already using a building material delivery board on your project, I’d encourage you to start. Ask these questions to get your trade partners to think through their deliveries, and you’ll quickly notice the improvement just one new Lean tool can make.